Why Nylon Cloth Tape Is the Most Reliable Choice for Everyday and Industrial Use?

When it comes to industrial tapes, we often think of strength, durability, and versatility. But have you ever wondered what makes Nylon Cloth Tape stand out from all the rest? Whether you’re dealing with home projects or high-demand industrial applications, this tape has a unique mix of toughness and flexibility that simply works.

Let’s dive into why Nylon Cloth Tape has become a favorite among technicians, DIY lovers, and manufacturers all over the world.

1. Built for Strength — Yet Easy to Handle

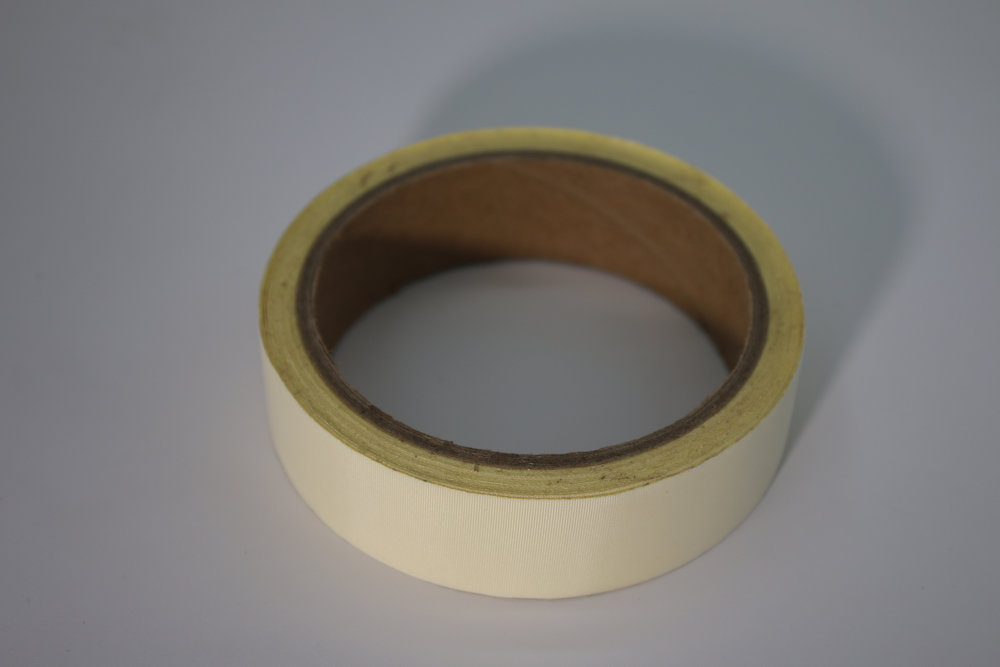

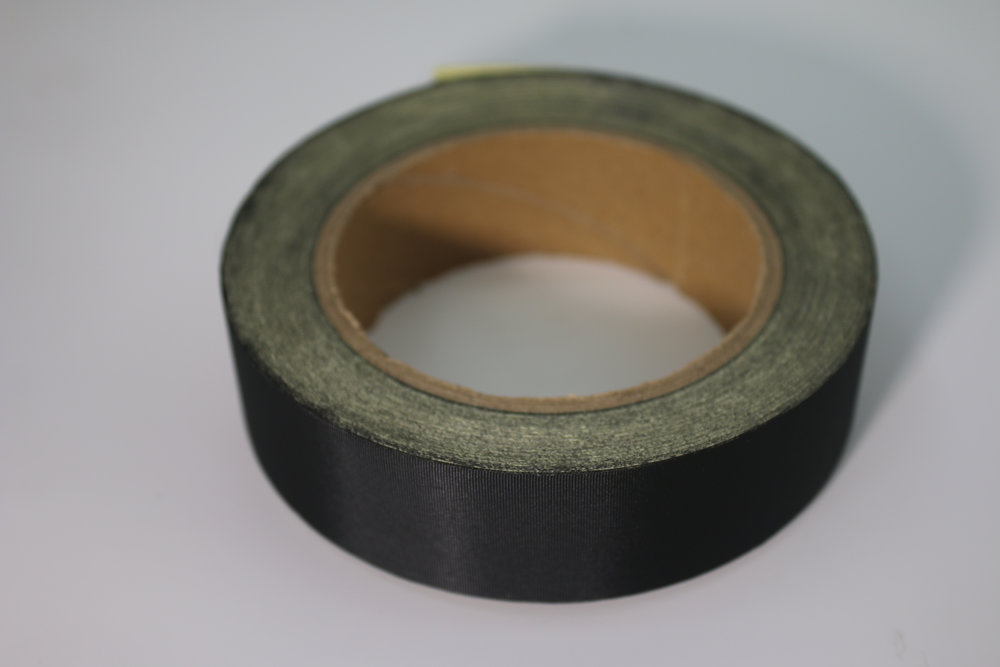

The first thing you’ll notice about nylon cloth tape is how strong it feels. Made from woven nylon fibers, it can handle pulling, twisting, and even bending without tearing. It’s way tougher than most plastic or paper-based tapes.

Despite its strength, nylon cloth tape is surprisingly flexible. You can easily wrap it around uneven surfaces, curved edges, or narrow gaps — no frustration, no slipping. It’s the kind of tape that adapts to your job, not the other way around.

And honestly, that’s one of the reasons many users just love it.

2. Perfect for Automotive and Electrical Applications

In the automotive industry, nylon cloth tape is widely used for wire harness bundling and noise reduction. It can handle the heat under a car’s hood, stay stable in vibration-heavy environments, and resist oil and dust.

Similarly, in electrical work, it offers great insulation performance, making it ideal for wrapping cables or fixing electrical joints safely. Because it’s abrasion-resistant, it keeps your wires protected even in tight spaces where rubbing or friction is common.

In short — it’s reliable, and reliability matters big time when safety’s involved.

3. Clean Appearance for Professional Results

Looks matter too, right? Especially in professional setups or visible installations. Nylon cloth tape has a matte, fabric-like finish that looks cleaner and more refined compared to glossy or plastic tapes.

Whether it’s used in office cable management, studio setups, or custom electronics, it gives a tidy, professional touch. That’s why many engineers and installers prefer it — it doesn’t just work well, it looks good doing it.

4. Weather Resistance and Long-Term Stability

Another major plus is its temperature and humidity resistance. Nylon cloth tape doesn’t lose adhesion even when exposed to heat, cold, or moisture. That makes it perfect for outdoor installations or factory environments where conditions are far from ideal.

It can even endure temperatures up to 105°C, maintaining strong adhesion while staying easy to remove when needed. No sticky mess, no residue — just smooth performance.

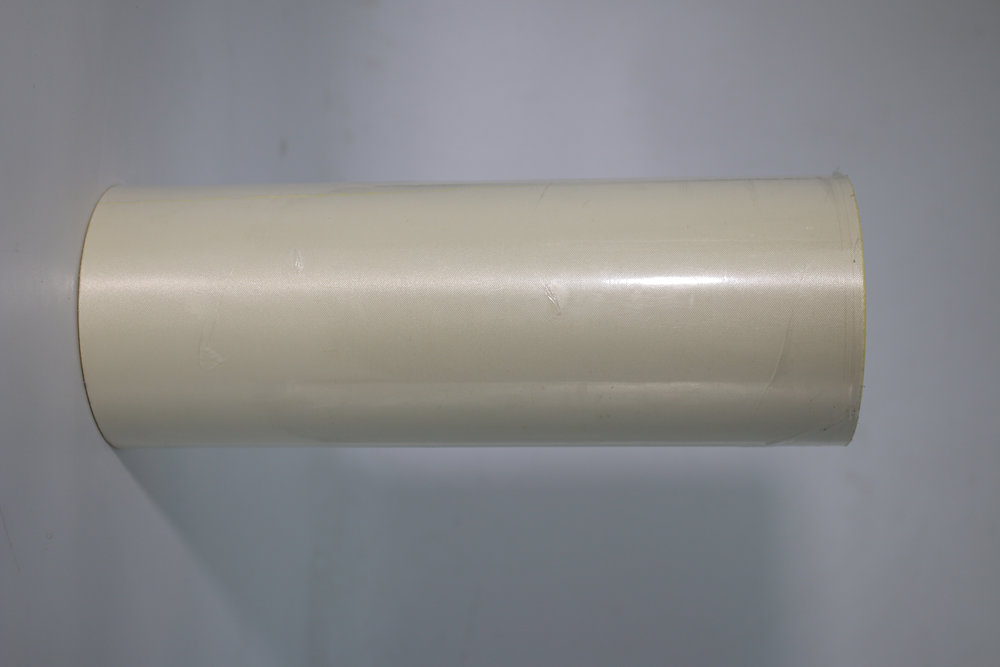

5. Easy Customization for Every Need

Here’s something many buyers appreciate: nylon cloth tape can be customized in width, color, and thickness. Whether you need a narrow tape for wiring or a wide one for surface protection, it’s totally doable.

Manufacturers like Anhui Yijiayi Technology Co., Ltd. offer complete customization services — from adhesive strength to fabric texture — so every roll matches your exact application needs.

And yep, that’s what makes it an excellent choice for both industrial users and small workshops.

6. Eco-Friendly and User-Safe Design

Unlike some older industrial tapes that release strong odors or harmful chemicals, nylon cloth tape is eco-friendly and odorless. It’s safe for both indoor and outdoor environments and meets modern environmental standards.

That’s a huge plus, especially for companies focusing on sustainable materials and workplace safety.

Wrapping Up

So, why is Nylon Cloth Tape the most reliable choice? Because it blends strength, flexibility, appearance, and durability in one simple roll. Whether you’re managing automotive wiring, securing cables, or finishing a neat DIY setup, it’s got you covered.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures