Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

At first glance, a control cabinet looks like a “safe” environment for electrical tape.

No rain, no sunlight, no direct mechanical impact—so any tape should last, right?

In reality, control cabinets create a unique aging environment that exposes the real difference between cloth tape and PVC tape over time.

So, which one actually lasts longer?

Let’s look at what really happens inside a cabinet.

1. Why Control Cabinets Are Tougher Than They Look

Control cabinets operate quietly—but continuously.

Inside, you’ll usually find:

-

Constant heat from power supplies and relays

-

Limited airflow

-

Long operating hours

-

Small but continuous vibration

These conditions don’t cause immediate failure, but they slowly age electrical tape day after day.

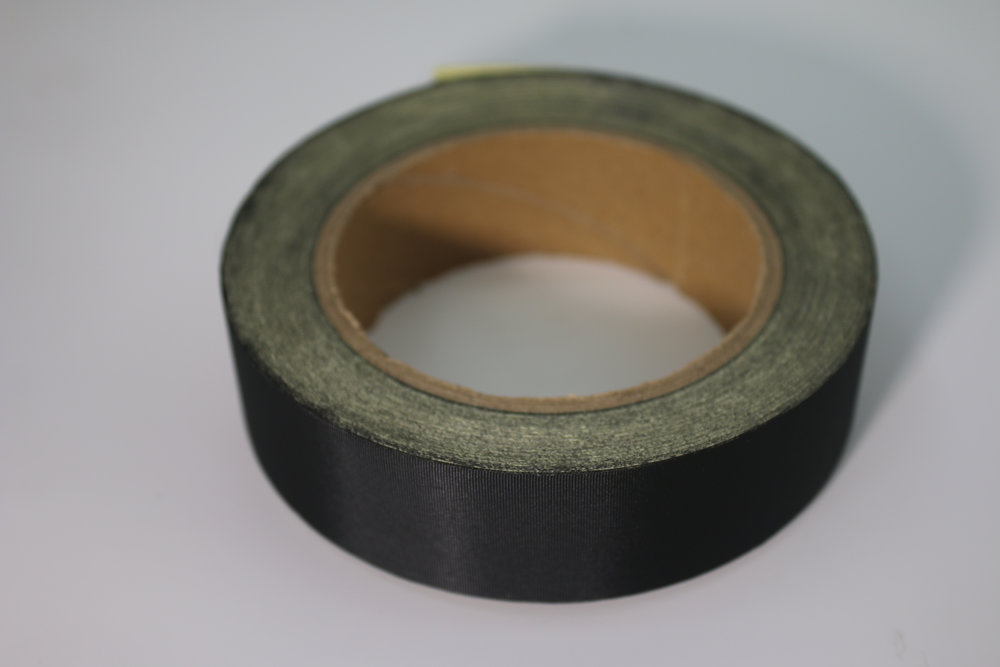

2. PVC Tape in Control Cabinets: Short-Term Convenience

PVC electrical tape is everywhere, mainly because it’s:

-

Cheap

-

Easy to apply

-

Widely available

In short-term or low-load wiring, PVC tape performs fine. But inside control cabinets, problems tend to appear over time.

Common PVC Tape Issues

-

Adhesive softening under heat

-

Edge lifting after months of operation

-

Loss of elasticity as plasticizers migrate

-

Sticky residue left behind during maintenance

PVC tape often looks “okay” at first, but after 12–24 months, performance can drop fast.

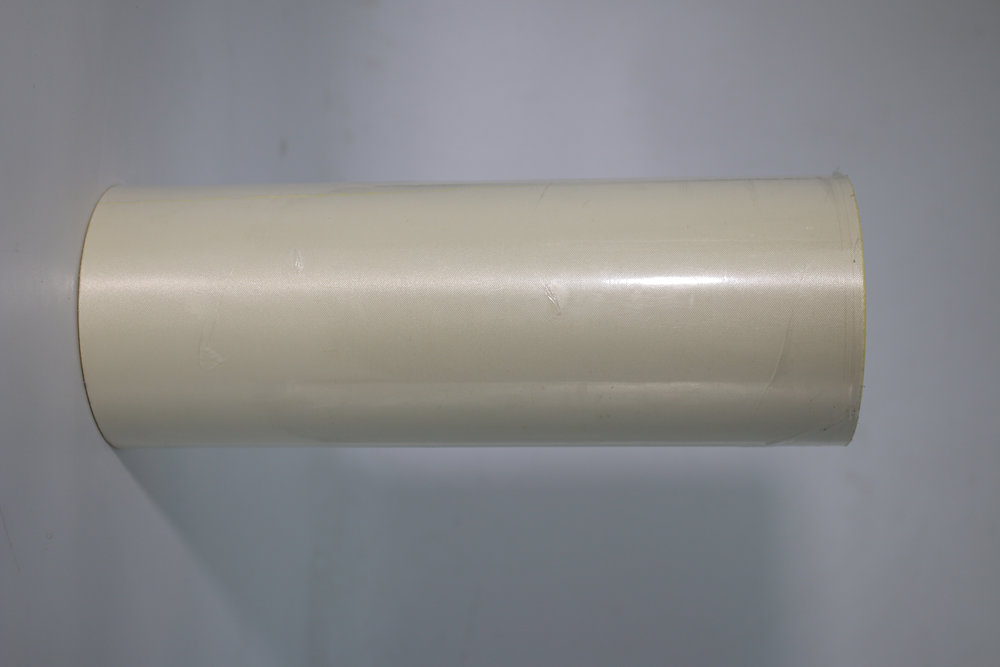

3. Cloth Tape: Designed for Long-Term Stability

Cloth-based electrical tapes (acetate cloth or nylon cloth) behave very differently.

Instead of relying on stretch, they rely on:

-

Fabric reinforcement

-

Dimensional stability

-

Heat-resistant adhesive systems

This makes cloth tape far more predictable over long service periods.

4. Heat Resistance: The Key Difference

Control cabinets usually operate in the 40–80°C range, sometimes higher near power components.

-

PVC tape gradually hardens or shrinks under constant heat

-

Cloth tape maintains shape and adhesion for much longer

That’s why cloth tape is commonly found in:

-

Industrial control cabinets

-

PLC panels

-

Automation systems

Heat aging is slow—but unavoidable.

5. Mechanical Stability Over Time

Even small vibrations matter.

Inside cabinets:

-

Doors open and close

-

Fans start and stop

-

Nearby equipment causes micro-movement

PVC tape depends on elasticity, which degrades over time.

Cloth tape relies on woven backing, making it far more resistant to loosening and creep.

6. Maintenance Reality: Removal Matters Too

Longevity isn’t only about how long tape stays in place—it’s also about what happens when it’s removed.

After long-term use:

-

PVC tape often leaves adhesive residue

-

Cloth tape usually peels cleanly

For maintenance teams, clean removal saves time and avoids secondary problems like dust adhesion or rewiring delays.

7. So, Which One Lasts Longer in Control Cabinets?

In real industrial control cabinets:

-

PVC Tape

Best for temporary fixes or low-heat, short-term use. -

Cloth Tape (especially nylon cloth)

Clearly lasts longer in terms of:-

Adhesion stability

-

Heat resistance

-

Mechanical reliability

-

Maintenance friendliness

-

That’s why cloth tape is increasingly specified for long-term control cabinet wiring.

Final Takeaway

If a control cabinet is expected to operate continuously for years, tape selection matters more than most people think.

PVC tape works—but cloth tape lasts.

And in industrial environments, lasting longer often means fewer failures, less maintenance, and better overall system reliability.

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes