Why Is Nylon Cloth Tape the Most Reliable Options for Wire Bundling?

In our previous blogs, we talked about how conductive fabric tape improves EMI shielding, and why automotive wire harness tape is essential for vehicle safety. Now, let’s move one step closer to everyday applications and focus on a product that quietly supports countless electrical systems: nylon cloth tape.

You might be wondering—with so many new materials available today, why is nylon cloth tape still widely used for wire bundling? The answer lies in its balance of flexibility, durability, and ease of use.

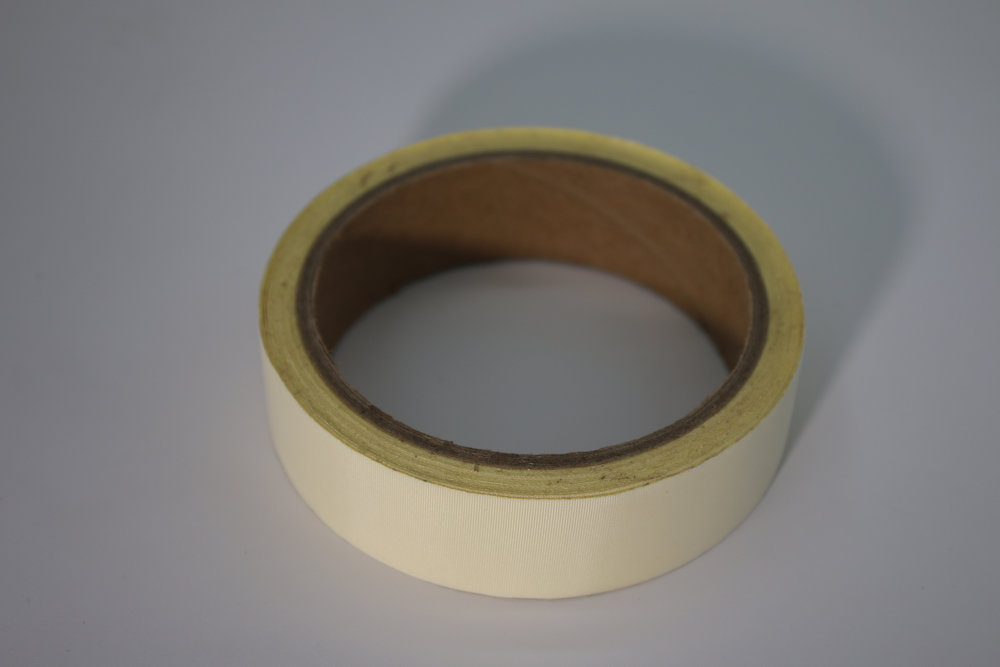

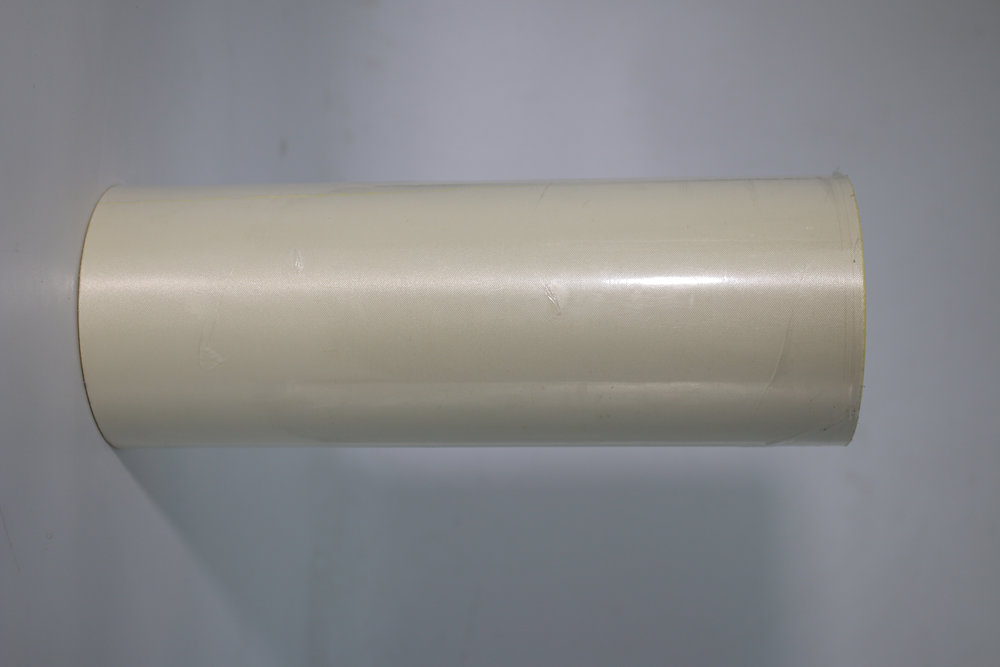

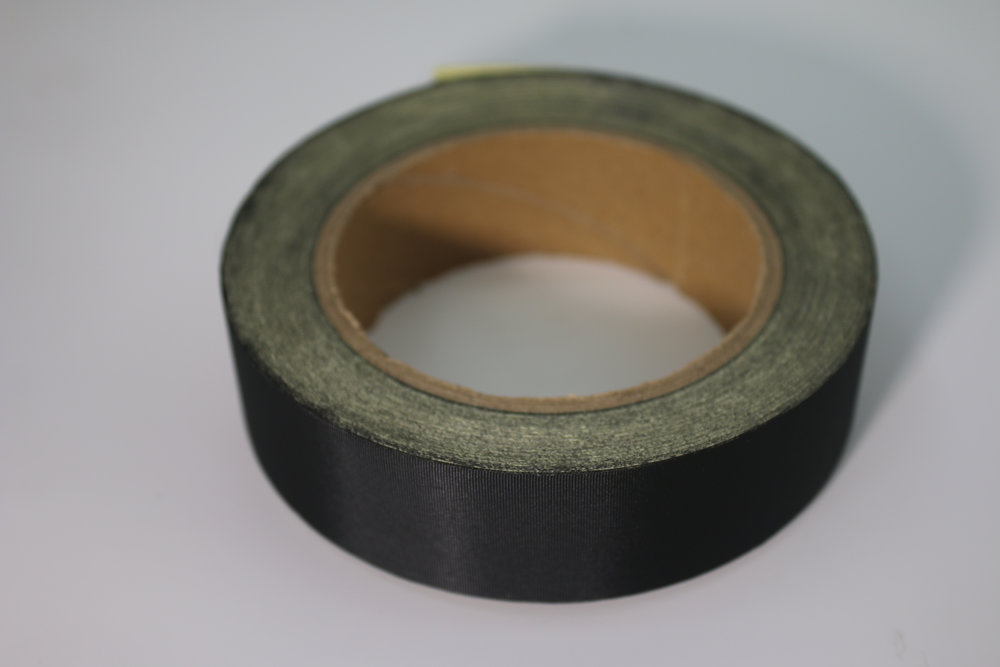

1. What Exactly Is Nylon Cloth Tape?

Nylon cloth tape is a fabric-based adhesive tape made from woven nylon fibers combined with a pressure-sensitive adhesive. Compared with PVC or basic electrical tape, it offers:

-

Higher tensile strength

-

Better abrasion resistance

-

Strong adhesion without residue

-

Long-term stability under vibration

This makes it a popular choice not only in industrial settings but also in daily-life electrical organization.

2. Why Is Nylon Cloth Tape So Popular for Wire Bundling?

Wire bundling is not just about making cables look neat. It’s about protecting wires from movement, friction, and damage.

Nylon cloth tape helps by:

-

Holding wire bundles firmly without cutting into insulation

-

Absorbing vibration, especially in vehicles and appliances

-

Reducing noise caused by loose or rubbing cables

In fact, many automotive harness solutions use nylon cloth tape as a base layer, working together with automotive wire harness tape for enhanced protection—this links directly back to our last article.

3. Everyday Applications You Might Not Notice

You probably encounter nylon cloth tape more often than you think. It is commonly used in:

-

Home appliances like refrigerators and air conditioners

-

Computer and TV internal wiring

-

Office equipment cable management

-

DIY electrical repairs and upgrades

And honestly, this tape is one of those products people only notice when something goes wrong. When used properly, it just works—no drama, no noise, no loose wires.

4. Performance That Lasts Over Time

One key reason nylon cloth tape remains reliable is its long-term performance. Unlike cheap tapes that harden, peel off, or leave residue, high-quality nylon cloth tape:

-

Maintains adhesion under heat and humidity

-

Resists aging and cracking

-

Stays flexible even after long-term use

This reliability is especially important when combined with other tapes like conductive fabric tape, where stable cable positioning directly affects shielding performance.

5. Easy to Apply, Easy to Maintain

From assembly lines to home users, nylon cloth tape is appreciated for its convenience:

-

Hand-tearable design

-

Easy repositioning during installation

-

Clean removal during maintenance

It makes wire management faster and cleaner, which is why technicians and OEM manufacturers continue to rely on it year after year. Sometimes simple solutions are still the best one.

6. A Smart Choice for Eco-Friendly Projects

Modern nylon cloth tapes can be produced with low-VOC adhesives and environmentally friendly processes. When sourced from a professional manufacturer, they meet both performance and sustainability requirements.

For companies and individual users alike, this makes nylon cloth tape a practical and responsible option.

Nylon cloth tape remains one of the most reliable options for wire bundling because it delivers consistent performance, long-term durability, and everyday convenience. When used alongside conductive fabric tape and automotive wire harness tape, it forms a complete cable protection solution across electronics, vehicles, and home appliances.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures