Why Is Automotive Wire Harness Tape Essential for Vehicle Safety and Longevity?

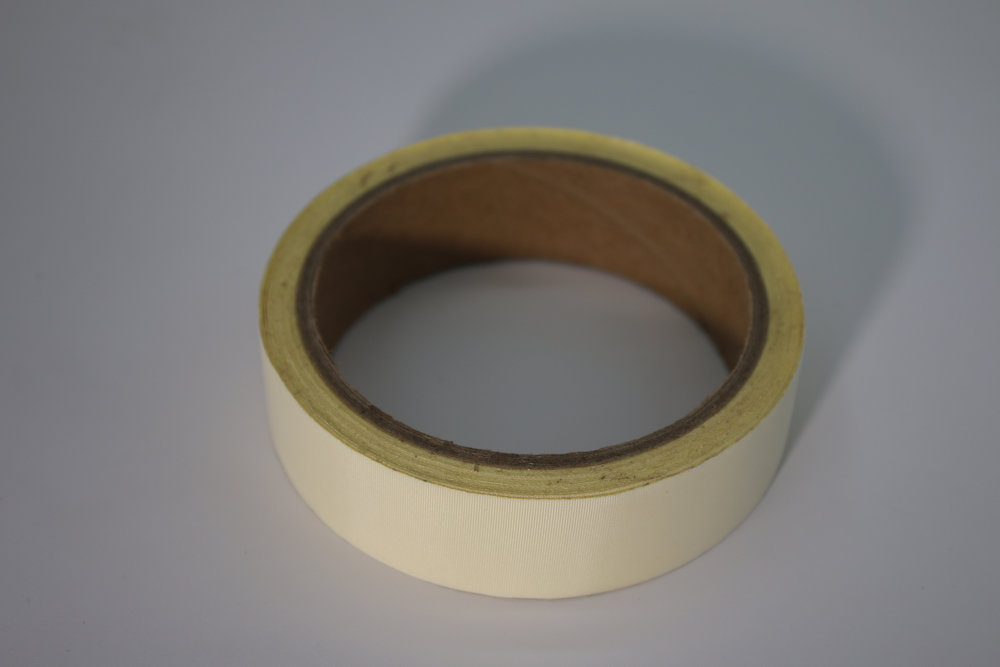

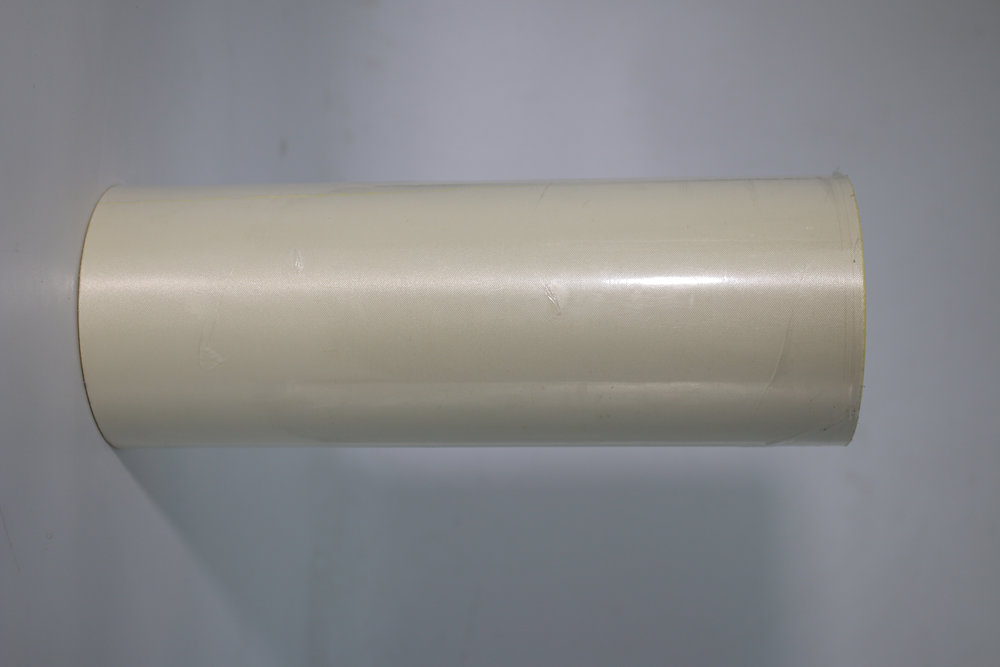

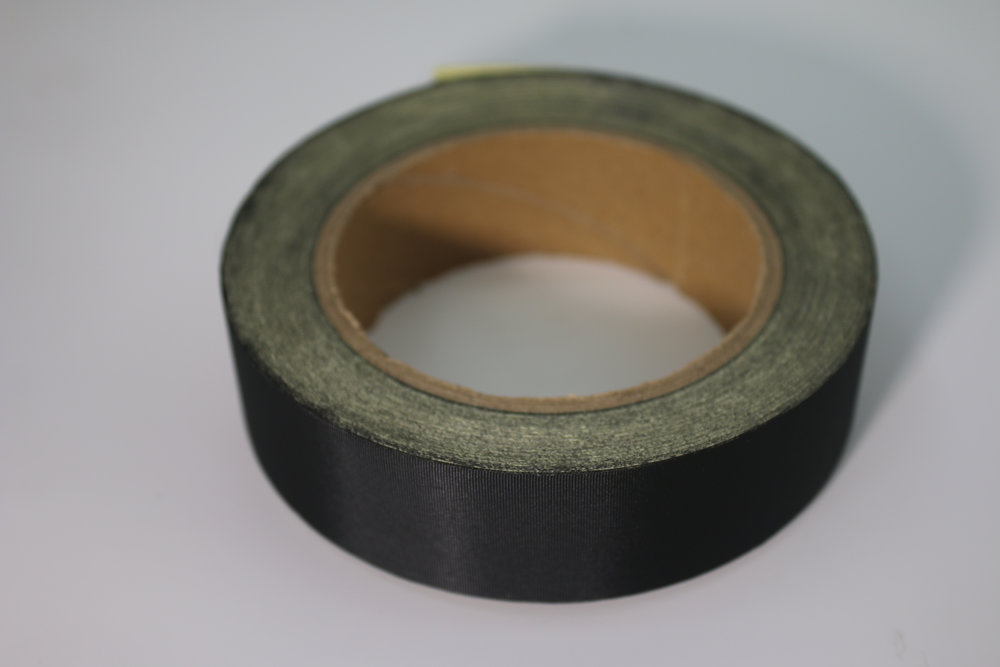

Modern vehicles are more complex than ever. With advanced electronics controlling everything from engine management to infotainment systems, keeping wires organized and protected is crucial. This is where automotive wire harness tape comes in—a simple yet vital solution to ensure safety, reliability, and long-lasting performance. Previously, we explored how conductive fabric tape reduces EMI; now, let’s dive into the automotive side of things.

But why should you really care about wire harness tape? Let’s explore.

1. What Makes Automotive Wire Harness Tape Different?

Unlike regular adhesive tape, automotive wire harness tape is specially designed for the harsh conditions found under the hood and inside vehicle cabins. Its key features include:

-

High temperature resistance (up to 150–200°C)

-

Flame retardancy and insulation properties

-

Superior adhesion to various wire materials

-

Flexibility to wrap around tight corners and complex shapes

And you know what? These tapes are often customized in width, thickness, and color, making them ideal for both OEM assembly and aftermarket repairs.

2. Enhancing Vehicle Safety

One of the main reasons to use automotive wire harness tape is safety. Poorly bundled wires can cause short circuits, fires, or system malfunctions. Wire harness tape helps by:

-

Insulating wires from heat and abrasion

-

Preventing loose connections that could lead to shorts

-

Maintaining organization to reduce stress on connectors

It’s kinda like we discussed in our previous blog about conductive fabric tape: using the right material can make a huge difference in device performance. In vehicles, the stakes are even higher.

3. Protecting Electronics and Reducing Noise

Wire harness tape isn’t just about keeping wires neat. It also helps protect sensitive electronics from interference and wear:

-

Shields wires from vibration-induced damage

-

Works with conductive tapes to reduce electromagnetic interference

-

Minimizes wear and tear from movement and friction

Yep, that’s right—proper taping can actually improve your vehicle’s electronic performance, just like we saw with EMI reduction in electronic devices.

4. Convenience for Assembly and Maintenance

Automotive wire harness tape is designed for easy application, which saves time during assembly and repairs. Key benefits include:

-

Peel-and-stick convenience

-

Conforms to irregular surfaces without tearing

-

Long-lasting adhesion even in hot, humid, or oily environments

5. Tips for Effective Use

To get the most out of your wire harness tape:

-

Clean wires before application for maximum adhesion.

-

Overlap tape layers slightly to improve insulation.

-

Avoid stretching tape excessively to maintain durability.

-

Use colored or labeled tapes for easy identification of circuits.

By following these steps, your vehicle’s wiring remains safe, organized, and reliable for years.

6. Environmentally Friendly Options

Modern automotive wire harness tapes can also be eco-friendly, low VOC, and compliant with automotive industry standards. Choosing high-quality products from reputable suppliers ensures safety, performance, and environmental responsibility.

Automotive wire harness tape is indispensable for vehicle safety, electronic reliability, and long-term durability. When combined with conductive fabric tapes and other industrial tape solutions from Anhui Yijiayi Technology Co., Ltd., it provides a comprehensive, high-quality, and customizable solution for automotive wiring challenges.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures