How Does Conductive Fabric Tape Help Reduce EMI and Improve Device Performance?

In today’s fast-paced electronics world, interference from electromagnetic signals is more common than many realize. From smartphones and laptops to industrial machinery, electromagnetic interference (EMI) can cause unexpected glitches, reduced performance, or even damage. This is where conductive fabric tape comes in—a solution that’s both practical and effective. In our previous blogs, we explored acetate cloth tape for household electrical safety; now, we extend that discussion to industrial and consumer electronics applications.

But how exactly does conductive fabric tape reduce EMI and improve device reliability? Let’s break it down.

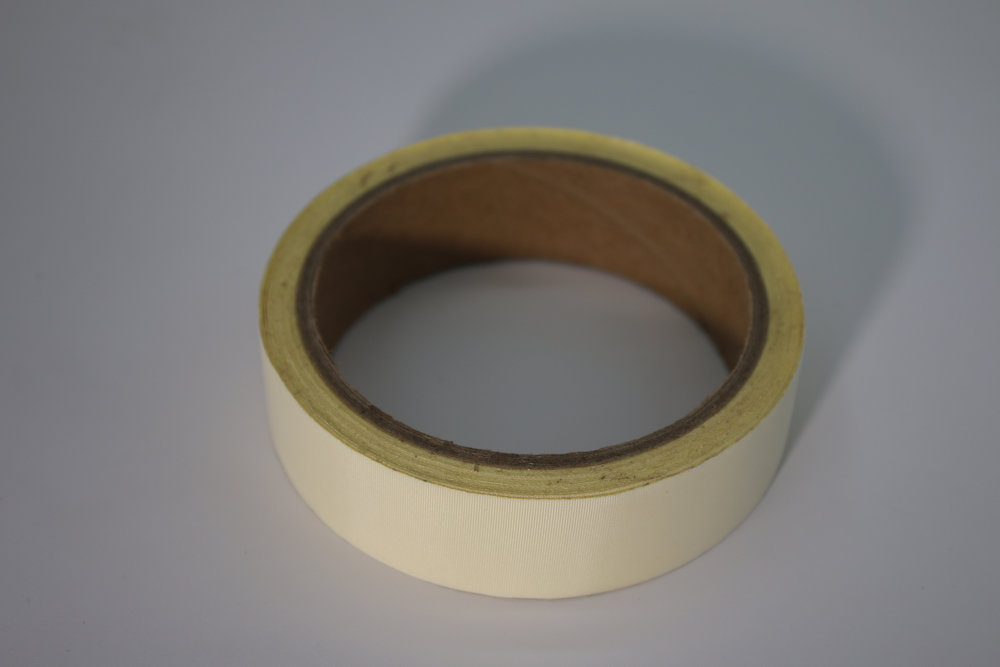

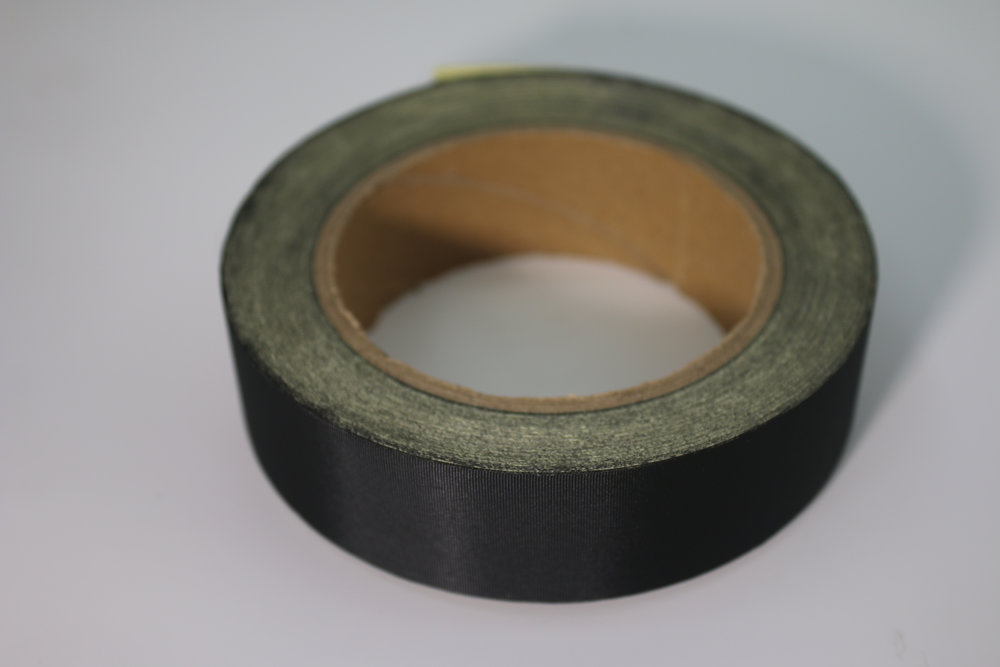

1. What Makes Conductive Fabric Tape Special?

Conductive fabric tape isn’t your everyday adhesive. It combines a flexible cloth substrate with conductive materials, usually silver or copper coatings. This combination allows the tape to:

-

Provide shielding against electromagnetic waves

-

Maintain excellent adhesion on irregular surfaces

-

Support long-term electrical conductivity

Unlike standard tapes, it not only holds components in place but also ensures that EMI does not disrupt sensitive circuits. And here’s the thing: if your devices constantly face signal issues, installing this tape can be a game-changer.

2. Reducing EMI in Consumer Electronics

Many household devices, including routers, TVs, and audio systems, are vulnerable to EMI. Using conductive fabric tape in device assembly helps by:

-

Shielding circuit boards from external electromagnetic noise

-

Preventing signal leakage from high-frequency components

-

Reducing unwanted crosstalk between wires

It’s just like we discussed with acetate cloth tape improving safety—the right material can make a huge difference in performance and reliability. Plus, this tape is flexible enough to be applied around complex shapes, which is crucial in compact electronics.

3. Supporting Industrial and Automotive Applications

Beyond consumer electronics, conductive fabric tape is widely used in automotive and industrial scenarios. For instance:

-

Automotive wire harnesses: Shielding sensitive sensors and controllers

-

Industrial control panels: Preventing machine malfunctions due to EMI

-

Medical equipment: Protecting highly sensitive monitoring circuits

And let me tell ya,the combination of flexibility and conductivity makes it much easier to retrofit devices or reinforce existing assemblies without disassembling the entire system.

4. Easy Installation and Long-Term Reliability

Conductive fabric tape is designed for convenience. Key features include:

-

Peel-and-stick application

-

Conforms to curved and irregular surfaces

-

High durability even under vibration or thermal changes

-

Long-lasting conductivity over years of use

These properties make it an excellent choice for both new assembly lines and maintenance tasks. As we saw with die-cut tapes, precision and adhesion are critical for reliable performance; conductive fabric tape takes it a step further by adding EMI protection.

5. Environmental and Safety Considerations

Many modern conductive tapes are eco-friendly, low VOC, and safe to use in sensitive environments. Choosing tapes from reputable suppliers ensures that not only performance but also regulatory compliance is maintained. And just like with acetate cloth and nylon cloth tapes, selecting high-quality products prevents premature failures and reduces maintenance costs.

6. Practical Tips for Users

To maximize performance:

-

Ensure the substrate surface is clean and dry before applying.

-

Overlap tape edges slightly to avoid EMI leaks.

-

Avoid sharp folds or excessive stretching to maintain conductivity.

-

Combine with other protective tapes if insulation or vibration resistance is also required.

Following these tips ensures that your devices remain stable and interference-free. Remember, one small material change can significantly enhance reliability.

Conductive fabric tape is a versatile, essential component for reducing EMI and improving device performance in consumer electronics, automotive, and industrial applications. Its combination of flexibility, conductivity, and adhesion makes it a must-have in modern electronic assembly.

As part of Anhui Yijiayi Technology Co., Ltd.’s tape series—including acetate cloth tape, nylon cloth tape, die-cut tape, and printable tape—conductive fabric tape continues to provide high-quality, customizable, and environmentally friendly solutions for diverse needs.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures