How Can Conductive and High-Adhesion Tapes Improve Industrial Equipment and Electronics Performance?

In modern industrial and electronic manufacturing, every detail counts. But have you ever thought about how something as simple as conductive tape or high-adhesion tape can significantly impact performance, safety, and efficiency? Let’s explore their critical applications and benefits in industrial machinery, electronics, and electrical components.

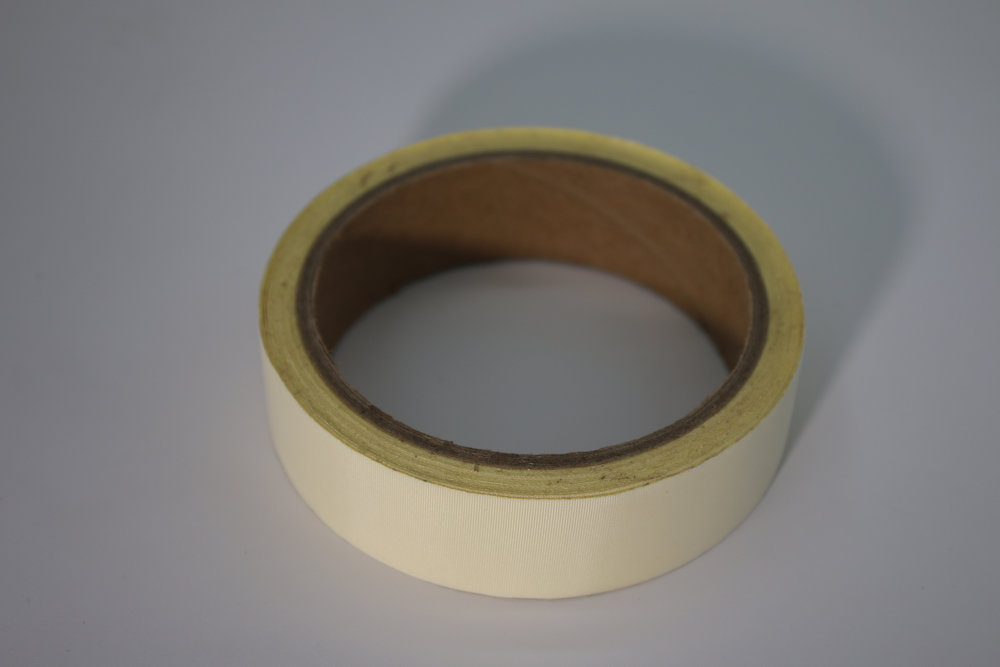

The Role of Conductive Fabric Tapes

Conductive fabric tapes are designed to carry electrical current while providing mechanical support. These tapes are widely used in:

-

EMI shielding for electronic devices

-

Circuit board grounding

-

Flexible connections in automotive sensors and industrial machinery

By using these tapes, manufacturers can reduce electromagnetic interference, prevent signal loss, and improve device reliability.

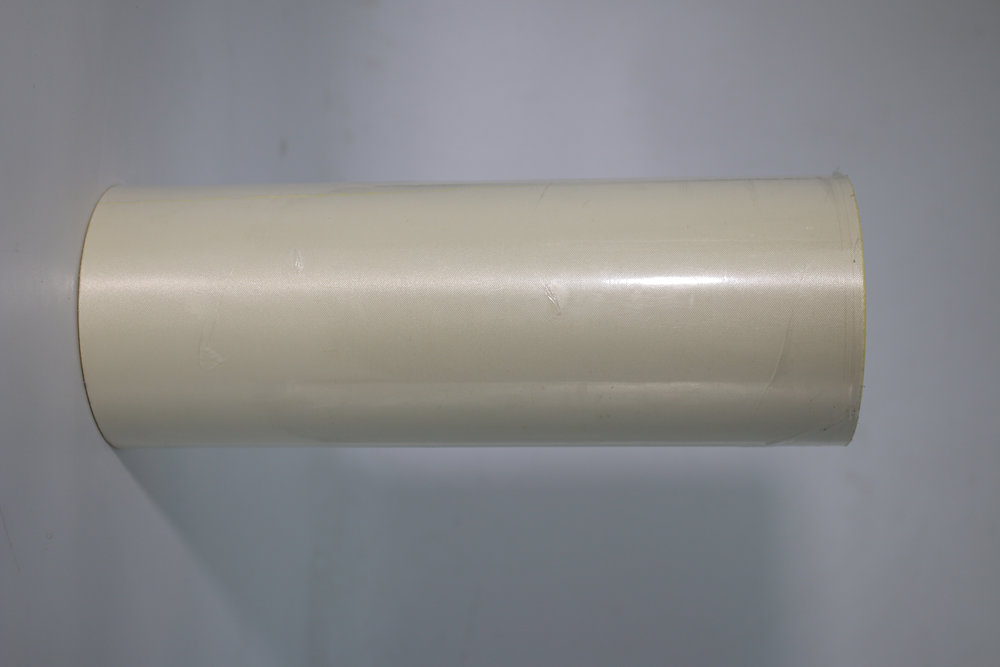

High-Adhesion Tapes for Industrial Applications

High-adhesion tapes are essential in heavy-duty industrial environments, where mechanical stress, vibration, and temperature changes are common. They provide:

-

Strong bonding for electrical insulation

-

Durable protection against oils, moisture, and abrasion

-

Versatility for machines, automotive parts, and control panels

Some high-adhesion tapes are customizable in thickness, width, and adhesive type, making them ideal for specific industrial or electronic applications.

Applications Across Electronics and Equipment

From precision electronics to industrial automation, these tapes play crucial roles:

-

Electronics Manufacturing: Fixing delicate components, insulating circuits, and shielding against EMI.

-

Industrial Machinery: Protecting sensors, motors, and wiring harnesses from heat, oil, and mechanical stress.

-

Automotive Electronics: Ensuring reliable sensor and wiring connections in electric and hybrid vehicles.

By choosing customizable tapes directly from manufacturers, companies can save time, reduce errors, and ensure compliance with UL, ROHS, and other safety standards.

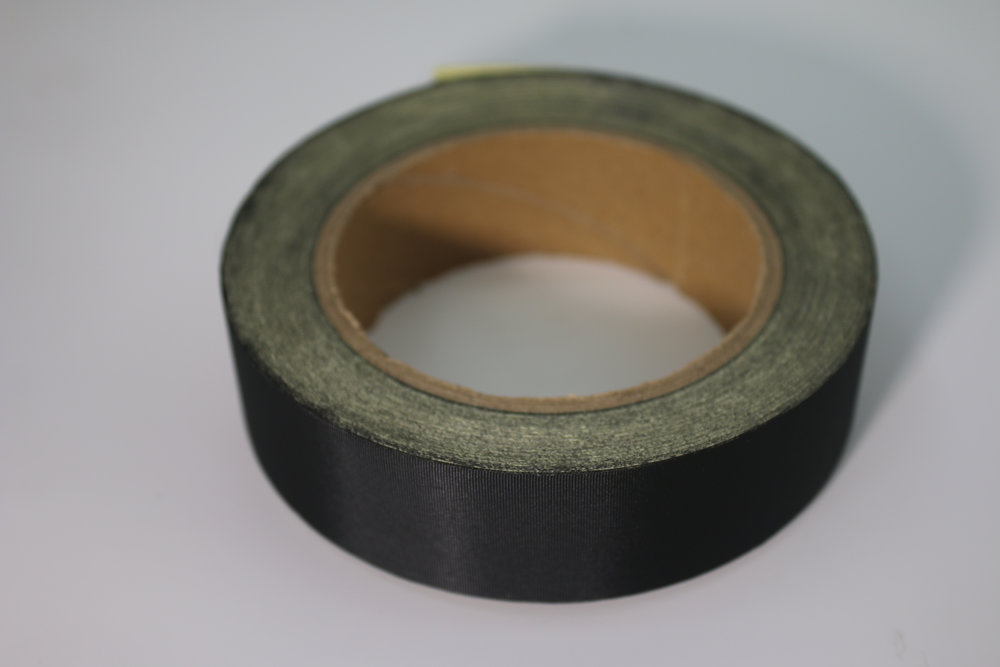

Customization and Factory Direct Benefits

A lot of companies underestimate the benefits of working directly with China-based manufacturers and suppliers. Direct sourcing offers:

-

Tailored solutions: choose thickness, width, color, and adhesive strength

-

OEM and bulk options: perfect for industrial and electronics production

-

High-quality, cost-effective solutions: factory-direct pricing reduces procurement costs

-

Wide range of products: including conductive fabric tape, high-adhesion tape, acetate cloth tape, and die-cut tapes

This approach ensures performance, reliability, and safety across industrial and electronic applications.

Why Conductive and High-Adhesion Tapes Matter

In short, the right tape can make a huge difference. They help prevent device failures, reduce maintenance costs, and enhance product lifespan. Whether it’s industrial automation, automotive electronics, or high-precision devices, these tapes are indispensable.

By sourcing from a trusted China-based manufacturer like Anhui Yijiayi Technology Co., Ltd., companies can access customizable, high-quality, and factory-direct solutions, suitable for both small-scale production and large industrial projects.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures