7 Ways Automotive Wire Harness Tape Improves Vehicle Safety and Performance

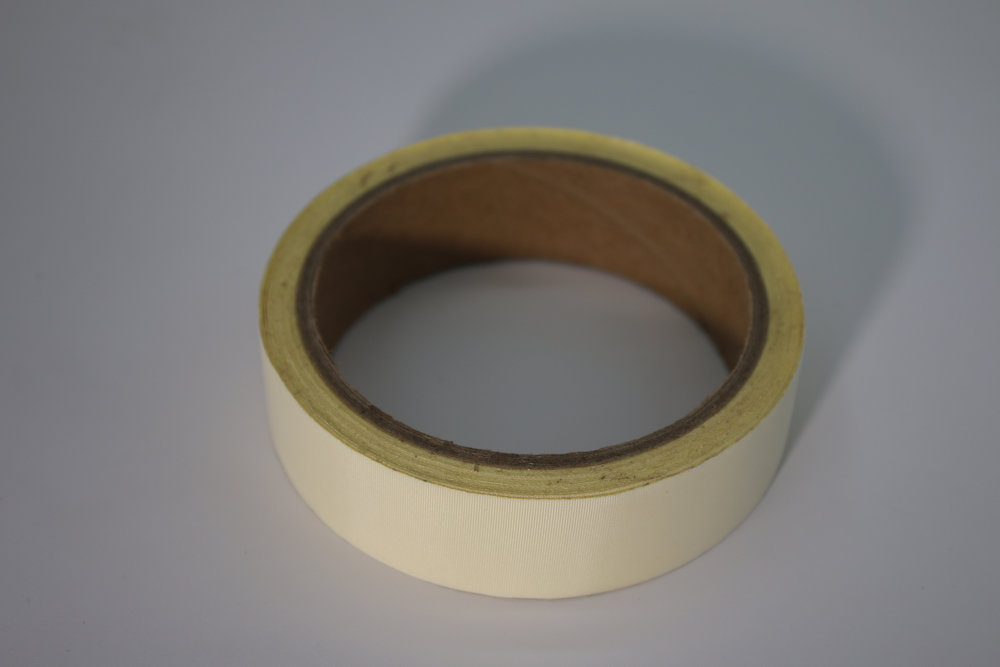

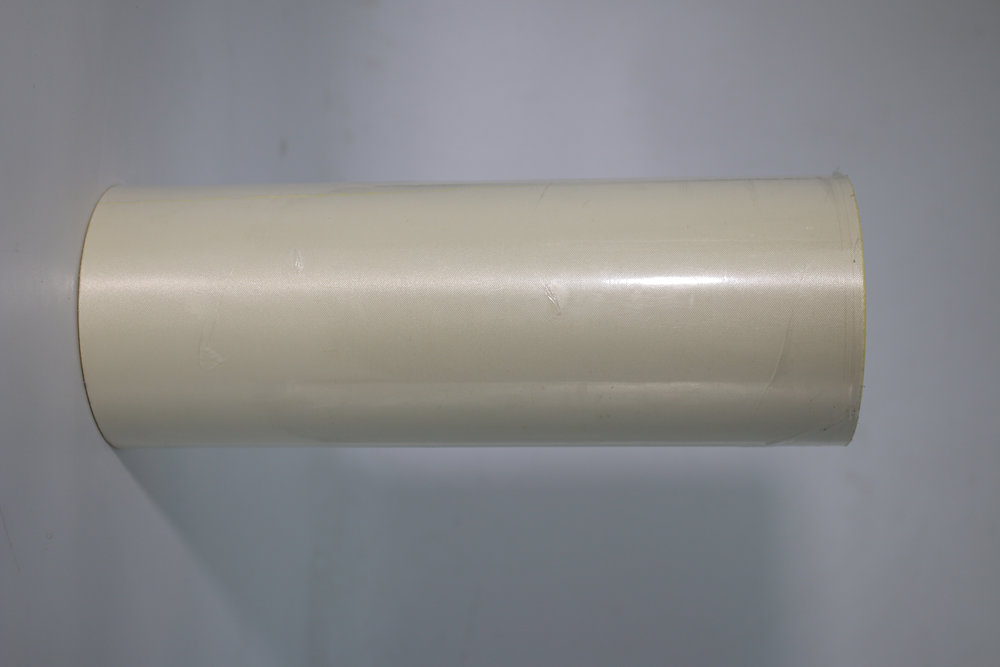

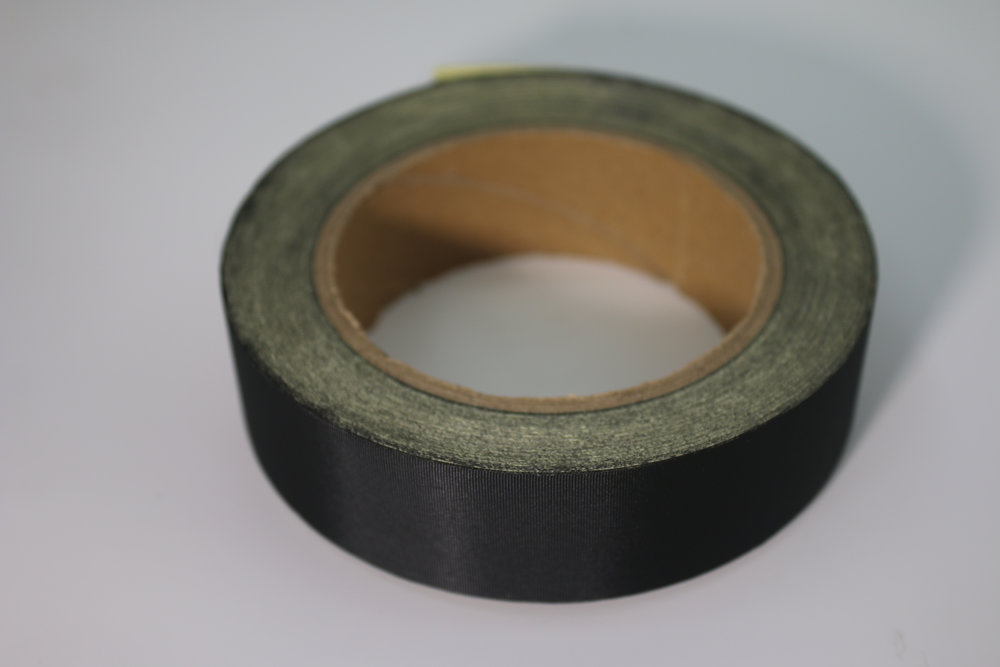

When you think about vehicle performance, you probably imagine engines, tires, or fuel systems. But there’s another unsung hero quietly keeping your car running safely — Automotive Wire Harness Tape. This specialized tape may look simple, but it plays a crucial role in protecting the complex electrical systems that modern vehicles rely on every second.

Let’s take a closer look at seven ways automotive wire harness tape helps improve both safety and performance on the road.

1. Protecting Wires from Heat and Vibration

Inside a car, temperatures can rise quickly, especially around the engine bay. Automotive wire harness tape provides strong thermal insulation, protecting wire bundles from heat, friction, and vibration. This prevents damage and extends the service life of the electrical system — something you’ll definitely appreciate over time.

2. Noise Reduction and Anti-Rattle Performance

If you’ve ever heard a faint rattle behind your dashboard, wire movement might be to blame. High-quality cloth-based harness tape helps reduce noise by securely binding wires together. The soft texture and flexibility absorb vibration, making your driving experience quieter and smoother.

3. Strong Abrasion Resistance

Automotive wiring often passes through sharp metal edges and tight spaces. Ordinary tape just can’t handle that. Wire harness tape is designed with a durable, abrasion-resistant surface that prevents cutting and wear, ensuring the integrity of the electrical network throughout the vehicle.

4. Easy Bundling and Maintenance

For car manufacturers and repair technicians, wire harness tape simplifies assembly. It allows wires to be bundled neatly, saving space and making future maintenance easier. The tape’s flexibility helps it conform to different shapes — even in narrow corners or uneven surfaces.

5. Enhanced Electrical Insulation

A reliable vehicle needs safe insulation. Automotive wire harness tape provides excellent dielectric strength, preventing short circuits or current leakage. Whether used in dashboards, doors, or engine compartments, it keeps your vehicle’s electrical system stable and safe.

6. Resistance to Chemicals and Moisture

Cars are exposed to oils, fuels, and humidity every day. The tape’s chemical and moisture resistance protects against corrosion and oxidation, maintaining consistent performance even in tough environments. It’s one of those “small details” that make a big difference in reliability.

7. Supporting Lightweight Vehicle Design

Modern cars aim to be lighter and more fuel-efficient. Instead of bulky plastic sleeves, automotive wire harness tape offers a lightweight solution with the same — or even better — protection. It helps reduce vehicle weight while keeping the electrical system just as secure.

Wrapping Up

From thermal protection to noise reduction, automotive wire harness tape is an essential part of every car’s design. It ensures safety, comfort, and reliability — all while making maintenance simpler. Next time you turn the key, remember that even the smallest materials can play the biggest roles in automotive engineering.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures