How Do Industrial and Electronic Adhesive Tapes Improve Efficiency and Safety?

In industrial manufacturing and electronic equipment assembly, adhesive tapes are more than just sticky strips — they are essential tools for efficiency, protection, and quality control. But what types of tapes are suitable for these applications, and how can they impact productivity? Let’s explore.

Conductive Fabric Tapes: Ensuring Reliable Electrical Performance

Conductive fabric tapes are widely used in electronics assembly, circuit boards, and EMI shielding applications. They provide consistent electrical conductivity, which prevents signal loss and interference. Using these tapes properly ensures electronic devices function reliably even under harsh industrial conditions.

Thermal Management Tapes: Heat Control Made Simple

Electronic components and machinery often generate heat, which can reduce performance or even cause damage. Thermal management tapes offer excellent heat dissipation and high-temperature resistance, making them ideal for LED modules, power electronics, and motor assemblies. By applying these tapes, manufacturers can extend equipment lifespan and maintain operational efficiency.

Die-Cut and Customizable Tapes: Precision and Flexibility

Industrial components come in various shapes and sizes, requiring precise tape application. Die-cut tapes allow for custom shapes, providing perfect coverage without excess material. This not only reduces waste but also simplifies assembly processes, saving both time and labor costs.

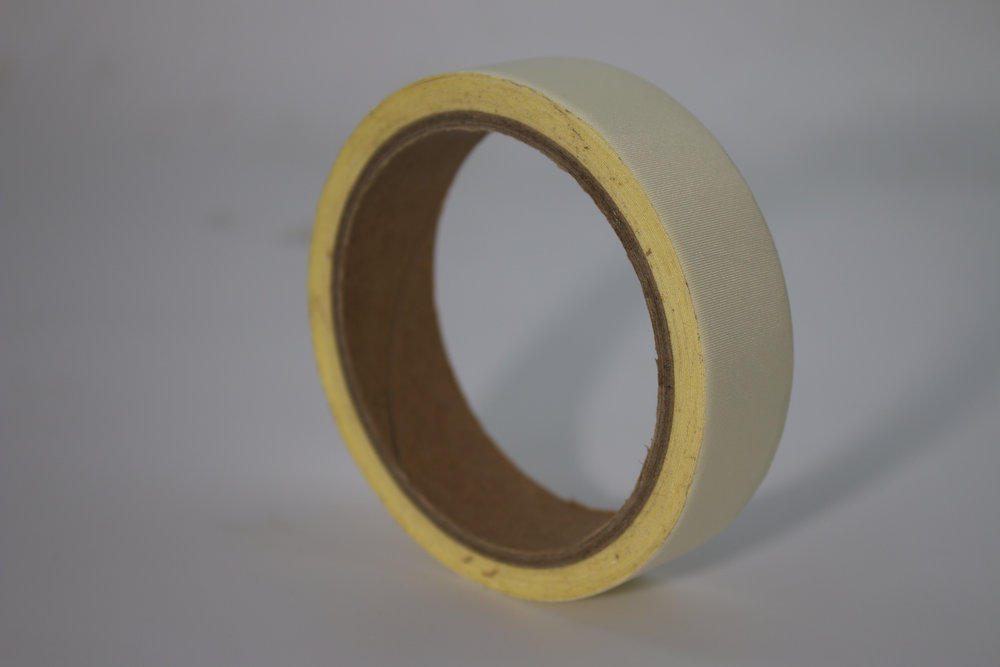

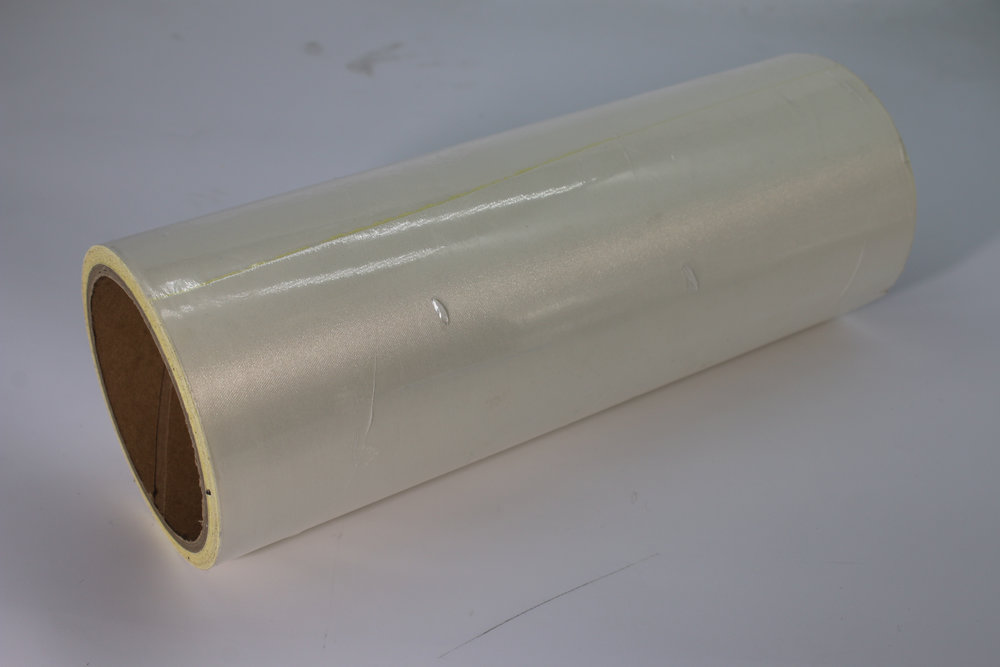

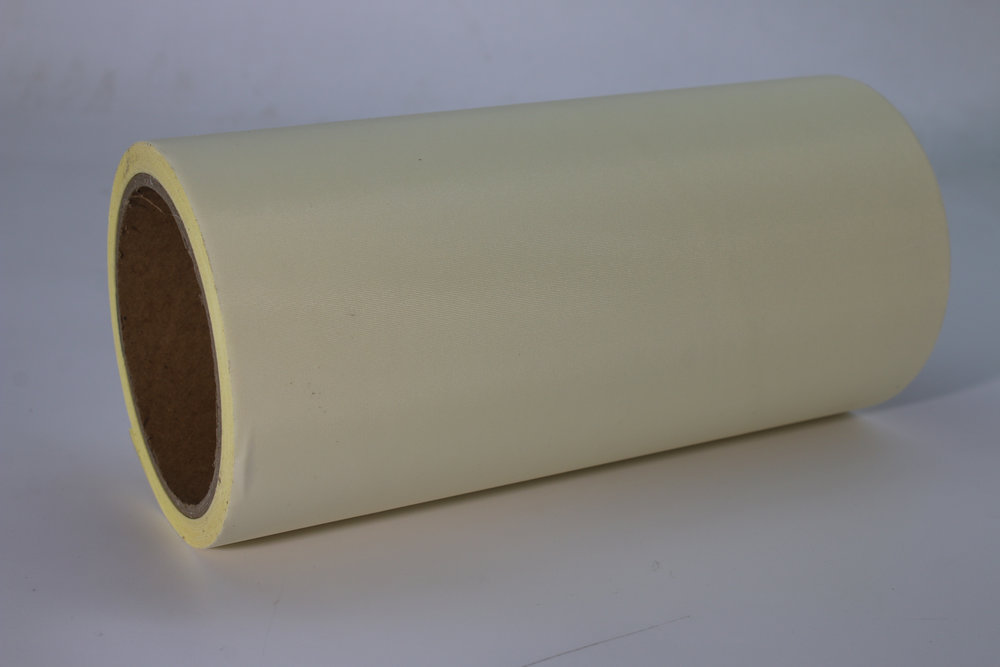

Acetate Cloth and Nylon Cloth Tapes: Durability and Insulation

Acetate cloth tapes are known for electrical insulation and thermal resistance, while nylon cloth tapes provide strong adhesion, abrasion resistance, and flexibility. These tapes are essential for industrial wiring, machinery protection, and electronic device assembly, ensuring both safety and durability.

Light-Blocking and Printable Tapes: Enhanced Functionality

Some industrial applications require light-blocking tapes to prevent unwanted reflections or interference in sensitive optical equipment. Printable tapes serve as labels for inventory, assembly guidance, and safety warnings, improving workflow efficiency and traceability.

Why Source from a Direct China Manufacturer?

Partnering with a China-based adhesive tape manufacturer like Anhui Yijiayi Technology Co., Ltd. provides several advantages for industrial and electronics clients:

-

Direct factory pricing and bulk order support

-

Customization of tape materials, dimensions, and adhesion levels

-

Compliance with global standards such as UL, ROHS, and ISO

-

Wide product range: conductive fabric tape, automotive wire harness tape, acetate cloth tape, nylon cloth tape, die-cut tape, light-blocking and printable tapes

-

Technical guidance for industrial assembly and electronics applications

This ensures clients receive high-quality, cost-effective solutions tailored to their unique requirements.

From electrical conductivity and heat management to precision die-cuts and labeling, adhesive tapes are crucial in industrial and electronic applications. By sourcing directly from a reliable China manufacturer and supplier, businesses can achieve better efficiency, safety, and product quality.

At Anhui Yijiayi Technology Co., Ltd., we provide factory-direct sales, OEM customization, and wholesale options, making us the go-to supplier for industrial and electronics adhesive tapes.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance