Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

When people talk about EMI shielding and electrical protection, conductive cloth tape and aluminum foil tape are usually the first two options that come up.

At a glance, both are conductive, both block interference, and both are widely used in electronics. But once heat enters the picture, the differences become much more noticeable.

In our previous blog, we explained why heat resistance matters when choosing tape for electrical equipment. Now let’s narrow it down and answer a more specific question many engineers and technicians ask:

👉 Between conductive cloth tape and aluminum foil tape, which one actually handles heat better in real applications?

Why Heat Performance Matters in EMI Shielding

Electronic devices generate heat constantly. Power boards, displays, motors, and control units all operate in environments where temperature slowly builds up.

If shielding tape cannot tolerate heat well:

-

Adhesive may soften or dry out

-

Conductivity may become unstable

-

Tape edges may lift or crack

-

EMI shielding effectiveness may drop over time

So the question isn’t just “is it conductive?”, but “does it stay conductive and stable under heat?”

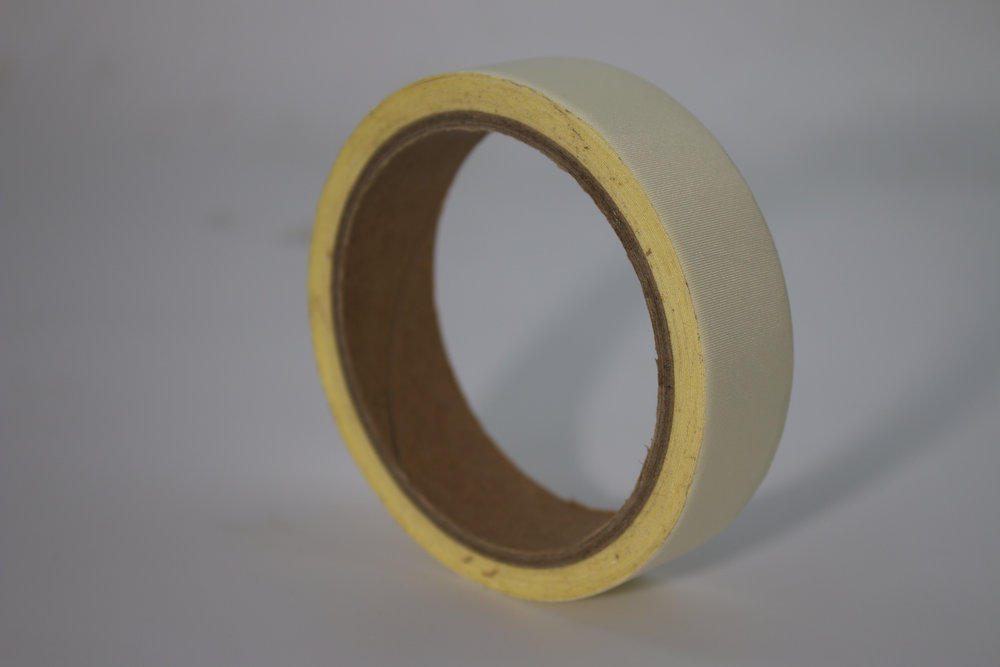

Understanding Conductive Cloth Tape

Conductive cloth tape typically uses:

-

A fabric backing (often polyester or similar)

-

Conductive coating (such as copper or nickel)

-

Pressure-sensitive adhesive, sometimes also conductive

Heat handling characteristics:

-

Good flexibility under elevated temperatures

-

Adhesive remains stable during long-term heat exposure

-

Less prone to tearing when heat and vibration combine

-

Maintains shielding performance over time

Because of its cloth structure, conductive cloth tape adapts better to uneven surfaces and tight spaces, which helps it perform more consistently when heat is present.

It is commonly used in:

-

Displays and touch panels

-

Consumer electronics housings

-

Automotive electronics

-

Industrial control cabinets

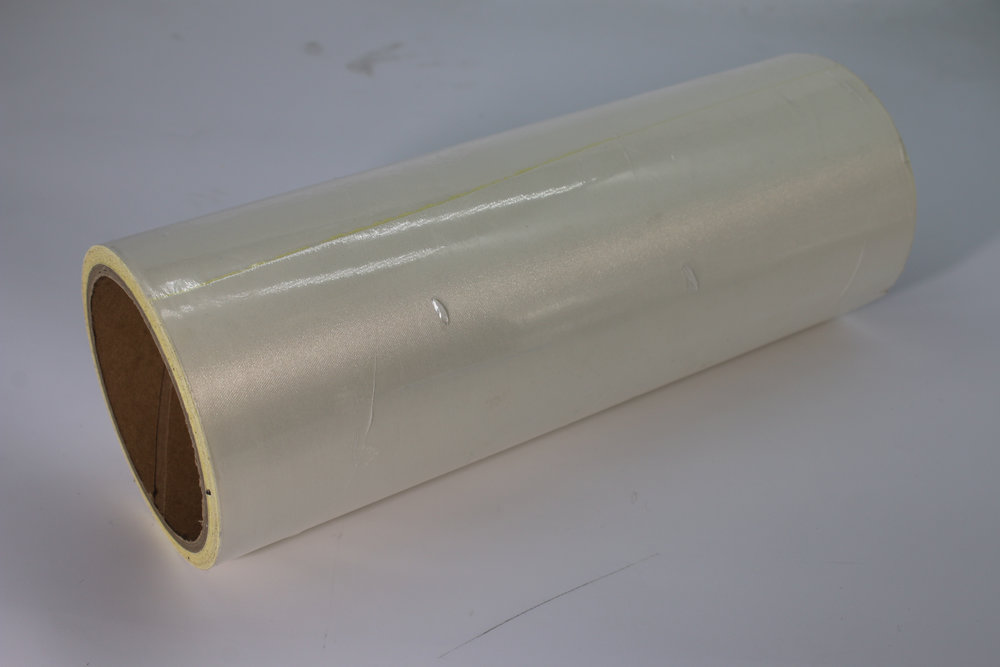

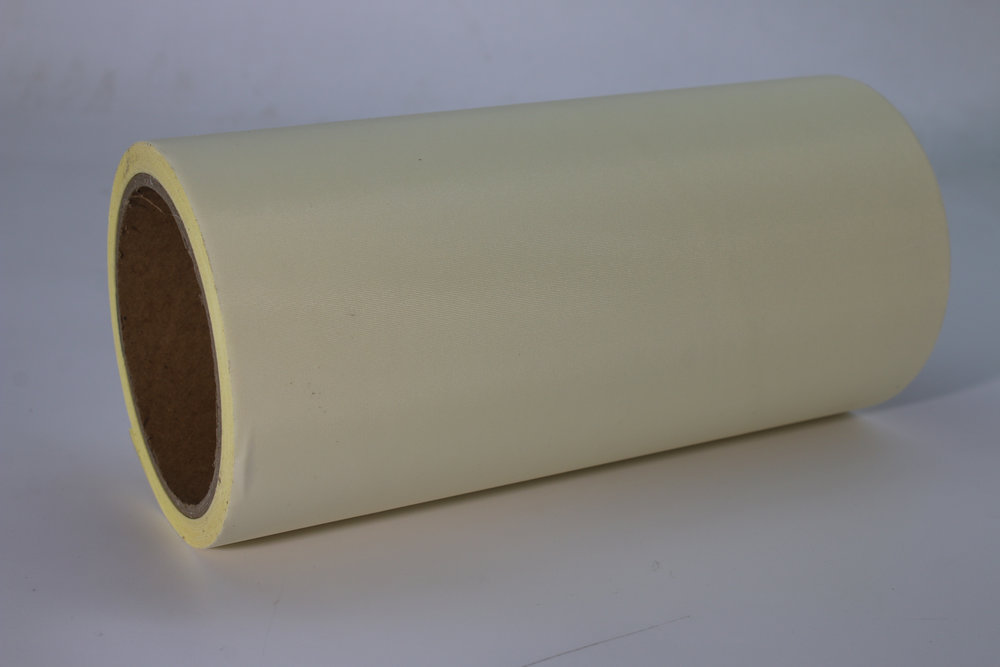

Understanding Aluminum Foil Tape

Aluminum foil tape uses:

-

Thin aluminum foil backing

-

Acrylic or rubber-based adhesive

Heat handling characteristics:

-

Aluminum itself tolerates high temperatures very well

-

Excellent initial heat reflection

-

Can lose flexibility when exposed to continuous heat

-

Foil may wrinkle, crack, or tear over time

In static, flat applications, aluminum foil tape performs well. However, when heat is combined with vibration, bending, or repeated expansion and contraction, performance may gradually decline.

It often used in:

-

HVAC systems

-

Insulation wrapping

-

Heat reflection applications

-

Grounding in fixed installations

Heat Resistance: Material vs System Performance

This is where many users get confused.

Yes, aluminum as a material handles heat extremely well. But tape performance is not only about the backing material, it’s about the whole system:

-

Backing

-

Adhesive

-

Flexibility

-

Long-term aging behavior

Conductive cloth tape usually offers better overall system stability under continuous operating heat, especially inside electronic devices where space is limited and components move slightly over time.

Sometimes aluminum foil tape looks stronger at first, but after months of heat exposure, it start losing adhesion faster than expected.

Adhesive Behavior Under Heat: A Key Difference

Under heat:

-

Conductive cloth tape adhesives are often formulated for electronics, focusing on aging resistance

-

Aluminum foil tape adhesives may harden or soften depending on formulation

Once adhesive performance drops, even the best conductive backing cannot do its job properly.

That’s why many electronics manufacturers prefer conductive cloth tape for long-term EMI shielding, especially in compact equipment.

Which One Handles Heat Better in Practice?

The answer depends on the application, but generally:

-

For continuous operating heat + vibration → conductive cloth tape

-

For short-term or static heat reflection → aluminum foil tape

-

For compact electronics and EMI shielding → conductive cloth tape

-

For HVAC and insulation → aluminum foil tape

Neither is “wrong”, but choosing the wrong one for a heat-exposed environment can create maintenance and reliability issues later.

Final Thoughts

When heat is involved, EMI shielding is not just about conductivity, but about long-term stability. Conductive cloth tape tends to handle real-world electronic heat conditions better, while aluminum foil tape excels in simpler, static thermal environments.

Understanding these differences helps avoid premature tape failure and keeps electronic systems running reliably for years.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance