How Do Automotive Adhesive Tapes Enhance Vehicle Safety and Performance?

In modern vehicles, adhesive tapes are everywhere — from wiring harnesses to battery packs, dashboards, and interior fittings. But how exactly do these tapes improve vehicle safety and performance, and why are they indispensable for automotive manufacturers? Let's dive in.

Automotive Wire Harness Tapes: Keeping Your Wiring Safe

Vehicles today have complex wiring systems connecting engines, sensors, and electronic controls. Automotive wire harness tapes are designed to bundle wires tightly, protect them from abrasion, and resist high temperatures. Using high-quality tapes ensures that wiring systems remain intact, even under extreme conditions, which reduces the risk of short circuits and electrical failures.

Heat-Resistant and Flame-Retardant Tapes: Protecting Critical Components

Engines and battery packs generate significant heat. High-temperature and flame-retardant tapes provide crucial insulation and fire protection, helping manufacturers comply with safety standards while protecting passengers and vehicle components. These tapes are commonly used in engine compartments, battery modules, and electrical panels.

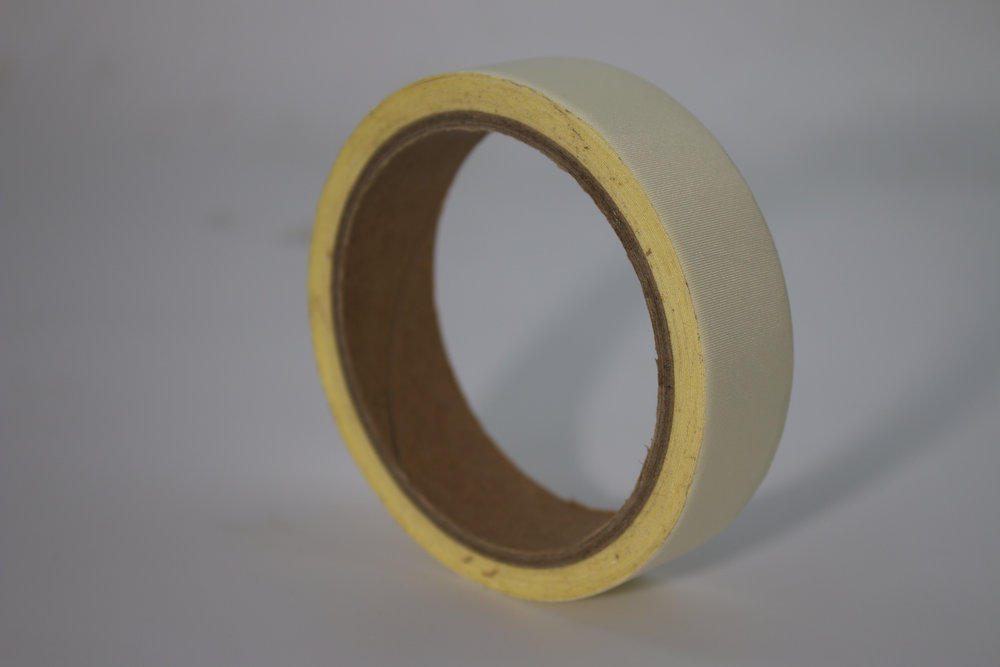

Acetate Cloth & Nylon Cloth Tapes: Durability Meets Flexibility

Automotive applications often require tapes that can withstand bending, vibration, and repeated assembly. Acetate cloth tapes offer electrical insulation and thermal resistance, while nylon cloth tapes provide strong adhesion and abrasion resistance. These tapes are perfect for dashboard wiring, electronic control units (ECUs), and door panels.

Die-Cut Tapes: Precision for Complex Automotive Parts

Modern vehicles use compact and intricate parts. Die-cut tapes allow for custom shapes and sizes, ensuring a perfect fit without excess material. They are widely applied in sensor assemblies, LED modules, airbag connectors, and infotainment systems, enhancing reliability and safety.

Light-Blocking and Printable Tapes: Enhancing Functionality

Certain automotive components, like instrument clusters and camera modules, need light-blocking tapes to prevent glare or interference. Printable tapes help with labeling, assembly guidance, and traceability in production lines. These features improve quality control and maintenance efficiency.

Why Choose a Direct China Manufacturer?

Sourcing directly from a China-based adhesive tape manufacturer and supplier like Anhui Yijiayi Technology Co., Ltd. brings several advantages for automotive businesses:

-

Factory-direct pricing and bulk order options

-

Customization of tape dimensions, adhesion strength, and materials

-

Compliance with global automotive standards (UL, ROHS, ISO)

-

Wide product range: automotive wire harness tape, acetate cloth tape, nylon cloth tape, die-cut tape, light-blocking and printable tapes

-

Technical support for industrial and automotive applications

This ensures manufacturers get high-quality, reliable tapes tailored to their specific automotive needs.

From wiring protection to fire safety, precision die-cuts, and labeling, high-performance adhesive tapes are vital for modern vehicle safety and performance. By choosing the right supplier, automotive manufacturers can enjoy cost-effective, customizable solutions without compromising quality.

At Anhui Yijiayi Technology Co., Ltd., we specialize in direct factory sales, OEM customization, and wholesale supply of automotive tapes, serving global clients as a trusted China manufacturer and supplier.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance