What Is Die-Cut Tape and Why It Matters for Industrial Applications

Whether you’re in electronics manufacturing, automotive assembly, or industrial labeling, chances are you've heard of die-cut tape—but maybe you're not quite sure what sets it apart or how it’s actually used across so many industries.

This guide will explain what die-cut tape is, why it's so important in modern production lines, and how China-based die-cut tape suppliers are helping global manufacturers reduce waste, save costs, and improve efficiency.

What Exactly Is Die-Cut Tape?

Simply put, die-cut tape refers to pressure-sensitive adhesive tape that’s been pre-cut into custom shapes or sizes using specialized tooling—called dies. Unlike traditional rolls, these custom-cut pieces can be designed to fit into complex assemblies without manual trimming.

There are different cutting methods, like:

-

Flat-bed die cutting (good for short runs or thick material)

-

Rotary die cutting (ideal for high-speed roll processing)

-

Laser die cutting (perfect for ultra-precise and intricate designs)

These methods allow for mass production of parts like:

-

Insulation pads

-

EMI shielding layers

-

Masking tape for PCB processes

-

Sealing tape in smartphones

-

Thermal transfer pads

And you know what? It’s super customizable. Like, insanely so.

Why Die-Cut Tape Matters in Industrial Settings

Let’s be real—industrial production is all about precision, speed, and reliability. Die-cut tape hits all three:

-

Precision

Each tape piece is made to fit exactly where it needs to go—no trimming, no extra cutting, just peel and stick. -

Efficiency

Pre-cut tapes reduce manual labor and speed up production lines. You don’t need to measure and cut each piece on-site. -

Clean Application

Since there's no on-site cutting, there's no dust, burrs, or adhesive mess. That’s huge for electronics or optics. -

Material Savings

By designing the die layout smartly, you minimize scrap. That means lower cost per unit. -

Packaging Flexibility

You can get die-cut tape in rolls, sheets, kiss-cut on liners, or even as individual parts. Whatever fits your line best.

Industries That Rely on Die-Cut Tape

Here’s a peek at where die-cut tape really shines:

-

Electronics & PCB assembly

Used for masking, insulation, bonding, and EMI shielding. -

Automotive sensors & dashboards

Precision-cut tapes help with heat resistance, bonding parts, and vibration damping. -

Medical device manufacturing

Die-cut hypoallergenic tapes help with skin adhesion, device sealing, and sterilization integrity. -

Home appliances & consumer goods

Used to fix LED panels, secure screens, or mount components without visible fasteners. -

Logistics & barcode systems

Die-cut printable tapes support on-demand labeling in warehouses.

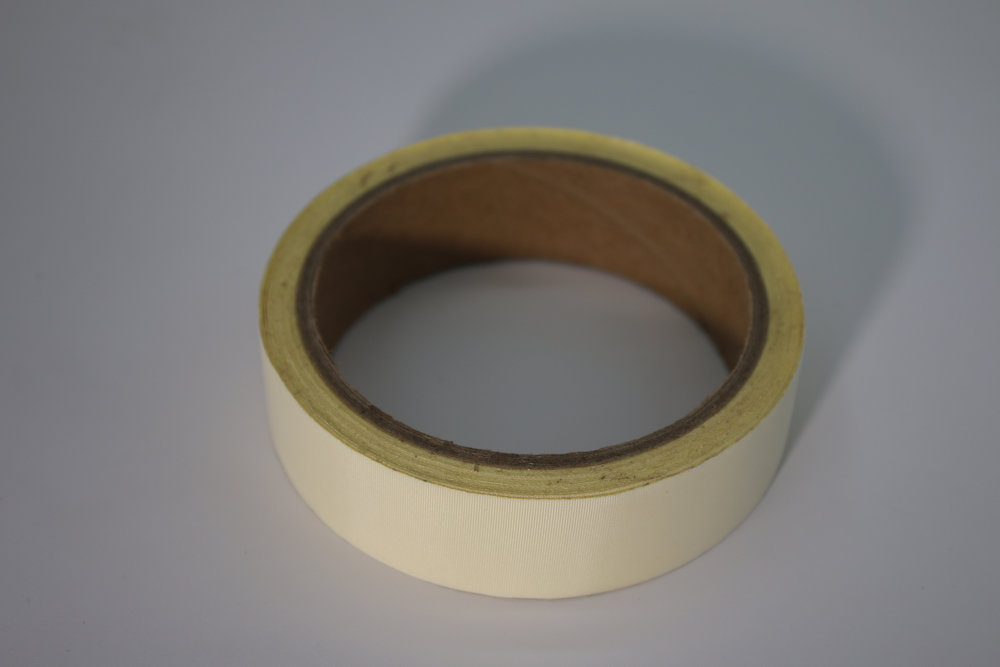

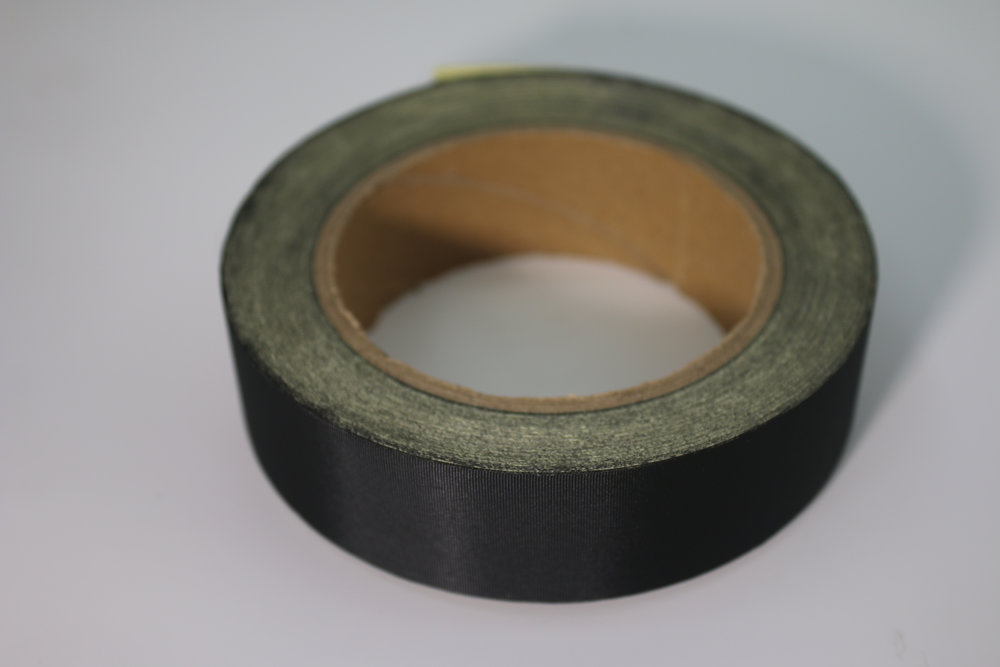

Common Materials Used in Die-Cut Tape

You can source die-cut adhesive tapes in a huge variety of materials:

-

PET for transparency and strength

-

Foam tape for cushioning and sealing

-

Kapton/PI for high heat resistance

-

Conductive fabric for EMI applications

-

Double-sided tapes for structural bonding

-

Non-woven fabric for flexible and lightweight parts

Quick note: We seen buyers pick the wrong material pretty often (yes, on accident). That can lead to delamination, weak bonding, or adhesive residue—so always confirm your specs.

Why Work With a China Die-Cut Tape Manufacturer?

If you’re sourcing in bulk, China-based die-cut tape suppliers offer some serious advantages:

-

Custom shape design based on your CAD files or physical samples

-

Factory-direct pricing (no middlemen markup)

-

Fast prototyping for new product launches

-

Material certification (RoHS, UL, REACH available)

-

Flexible order volumes, from samples to mass production

-

OEM/ODM support for branded or private-label tape

Basically, it’s your one-stop shop for all things tape.

Final Thoughts

Die-cut tape isn’t just another packaging product—it’s a smart solution that improves accuracy, productivity, and consistency across industries. Whether you're producing medical devices, automotive sensors, or mobile phones, custom die-cut adhesive solutions can transform your process.

So, if you're planning your next sourcing move, don’t forget to consider die-cut tape—and maybe partner with a reliable China manufacturer and supplier who knows their stuff.

Got questions? Don’t be shy—reach out and let’s talk tape.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures