Is Conductive Fabric Tape the Ultimate Solution for EMI Shielding and Grounding?

When it comes to modern electronics, EMI (electromagnetic interference) can be a serious headache. Engineers, OEMs, and manufacturers are constantly looking for reliable ways to shield devices, ground components, and ensure stable performance. This is where conductive fabric tape comes into play. But is it really the best solution for EMI shielding and grounding? Let’s dive in.

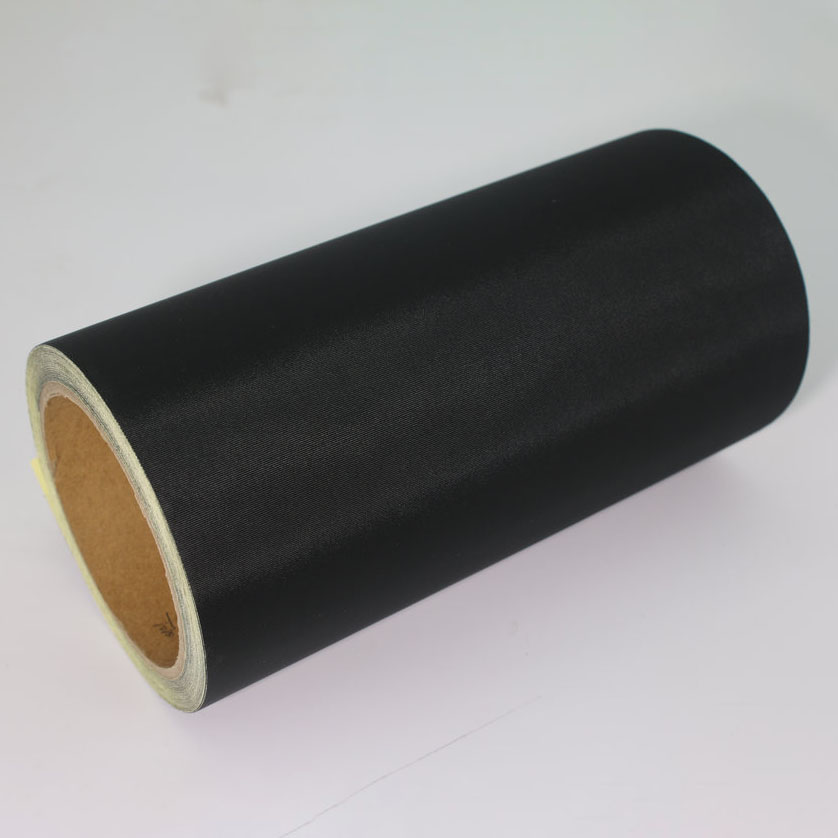

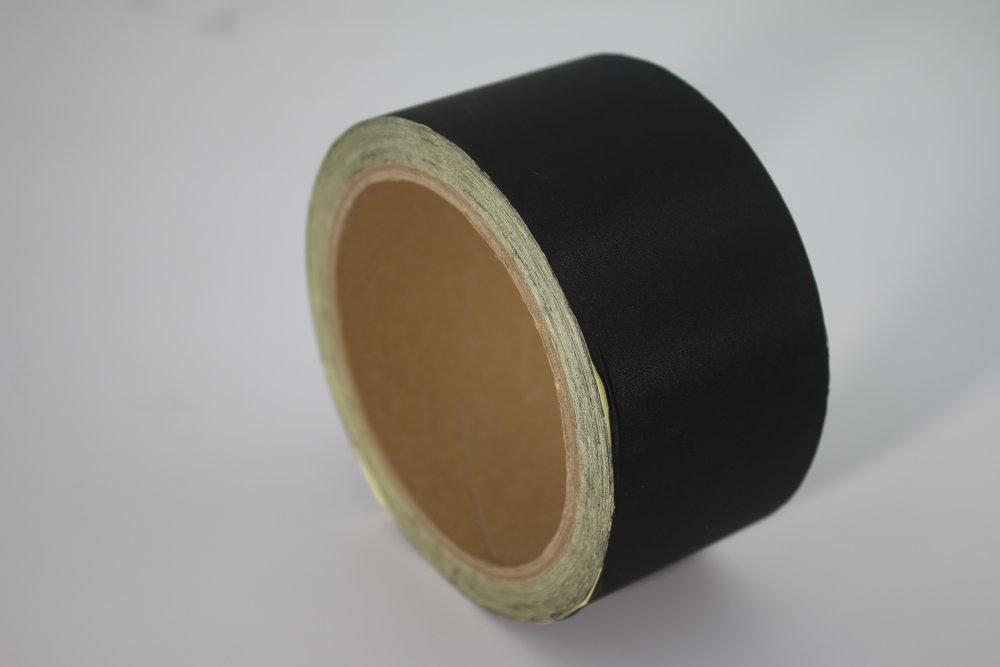

What is Conductive Fabric Tape?

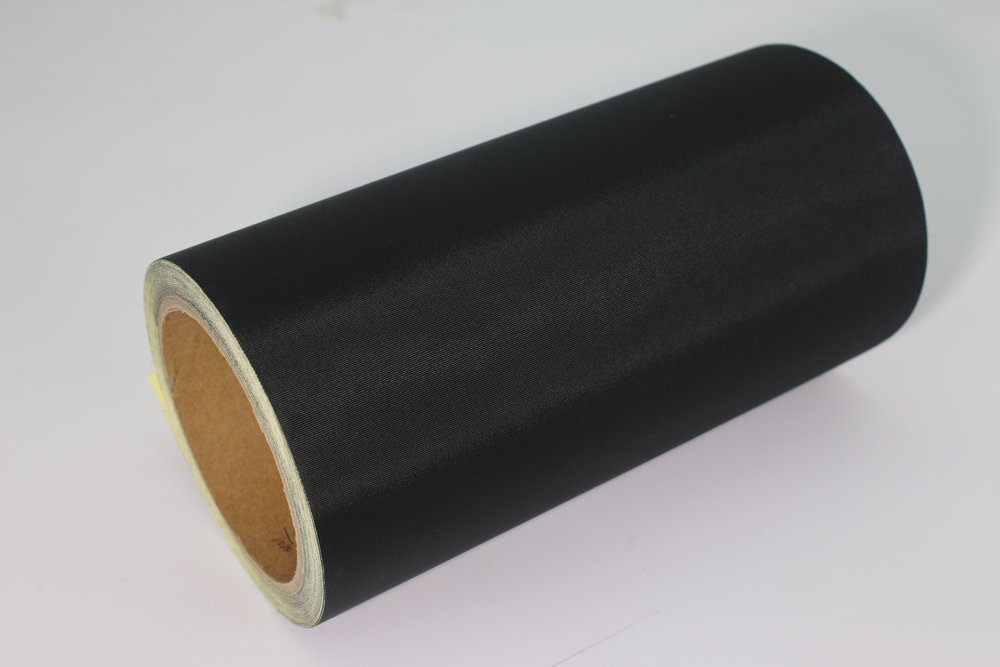

Conductive fabric tape is a specialized adhesive tape made with conductive fabric material such as taffeta or non-woven fabric coated with conductive particles (like nickel or copper). It combines electrical conductivity, flexibility, and strong adhesion — making it one of the most versatile EMI shielding products on the market.

At Anhui Yijiayi Technology Co., Ltd., a China-based conductive fabric tape manufacturer and supplier, we specialize in direct factory sales, OEM customization (color/size), and wholesale supply. Our tapes are widely used in electronics, telecommunications, automotive, and aerospace industries.

Key Benefits of Conductive Fabric Tape

Why do engineers and manufacturers prefer this tape? Here are some highlights:

-

Excellent EMI Shielding – Prevents signal interference in smartphones, laptops, and communication equipment.

-

Grounding Performance – Ensures reliable electrical continuity between components.

-

Flexibility & Durability – Adapts to curved surfaces, connectors, and irregular shapes without losing conductivity.

-

Easy Customization – Can be die-cut, slit, or laminated to meet specific OEM designs.

-

Reliable Adhesion – Stays in place even in high-humidity or high-temperature environments.

So yeah, it’s not just a tape — it’s a functional material that protects your devices from failure.

Common Applications

Conductive fabric tape is widely used across industries:

-

Consumer Electronics: Smartphones, tablets, laptops, gaming consoles.

-

Telecommunications: Routers, antennas, 5G base stations.

-

Automotive: EV battery packs, infotainment systems, sensor grounding.

-

Aerospace & Defense: Shielding avionics and radar equipment.

-

Industrial Equipment: Control panels, robotics, and automated machinery.

And here’s the cool part: It can even be used in medical devices where EMI shielding is critical for patient safety.

Why B2B Buyers Choose Direct Factory Supply

When sourcing conductive fabric tape, industrial buyers and OEMs care about:

-

Consistency in conductivity and adhesion

-

Custom widths and die-cut shapes

-

UL, ROHS, and REACH certifications

-

Bulk roll supply for automated assembly lines

-

Cost-effective wholesale options

By working with a China manufacturer like Anhui Yijiayi Technology Co., Ltd., buyers get better pricing, faster lead times, and technical support compared to middlemen or resellers.

How to Select the Right Conductive Fabric Tape

Not all conductive tapes are equal. When choosing, consider:

-

Surface Resistance: Measured in ohms/sq, lower values mean better conductivity.

-

Adhesive Type: Acrylic adhesives are long-lasting, while conductive adhesives ensure continuity through the bond line.

-

Thickness: Thinner tapes are flexible, thicker ones provide mechanical strength.

-

Shielding Effectiveness: Tested in dB across frequency ranges.

Small detail, but trust me — choosing the right one can save you from product recalls or costly redesigns.

So, is conductive fabric tape the ultimate EMI shielding and grounding solution? For many industries, the answer is yes. With its balance of conductivity, flexibility, and cost-efficiency, it outperforms traditional shielding foils or coatings in a wide range of applications.

At Anhui Yijiayi Technology Co., Ltd., we provide direct factory sales, OEM conductive fabric tape customization, and global wholesale supply. Whether you need bulk rolls, die-cut parts, or custom laminations, we are your trusted China supplier for high-quality conductive tapes.

5 Ways Nylon Cloth Tape Solves Everyday Industrial and Consumer Challenges

5 Ways Nylon Cloth Tape Solves Everyday Industrial and Consumer Challenges

How Printable Tape Improves Labeling Efficiency Across Industries?

How Printable Tape Improves Labeling Efficiency Across Industries?

How Light-Blocking Tape Enhances Product Performance in Modern Devices?

How Light-Blocking Tape Enhances Product Performance in Modern Devices?

Why Light-Blocking Tape Matters More Than You Think in Modern Electronics

Why Light-Blocking Tape Matters More Than You Think in Modern Electronics

Why Nylon Cloth Tape Is the Most Underrated Tool in Every Industry

Why Nylon Cloth Tape Is the Most Underrated Tool in Every Industry

How Automotive Wire Harness Tape Protects and Organizes Your Vehicle Wiring System

How Automotive Wire Harness Tape Protects and Organizes Your Vehicle Wiring System

Light-Blocking Tape: Why It Matters in Modern Display and Lighting Design

Light-Blocking Tape: Why It Matters in Modern Display and Lighting Design

Printable Tape: How It Enhances Design and Functionality

Printable Tape: How It Enhances Design and Functionality

Why Is Conductive Cloth Tape So Important in Modern Electronics?

Why Is Conductive Cloth Tape So Important in Modern Electronics?

How Conductive Cloth Tape Improves Electronic Shielding and EMI Protection

How Conductive Cloth Tape Improves Electronic Shielding and EMI Protection