How Automotive Wire Harness Tape Protects and Organizes Your Vehicle Wiring System

In our previous blogs, we explored how Conductive Cloth Tape enhances EMI protection, how Printable Tape improves identification and labeling, and how Light-Blocking Tape refines display precision. But when it comes to automotive applications, there’s one unsung hero holding everything together — quite literally — Automotive Wire Harness Tape.

It may not look fancy, but this tape is a crucial part of your vehicle’s electrical backbone. So, what exactly does it do, and why do automakers trust it so much? Let’s get into it.

1. What Is Automotive Wire Harness Tape?

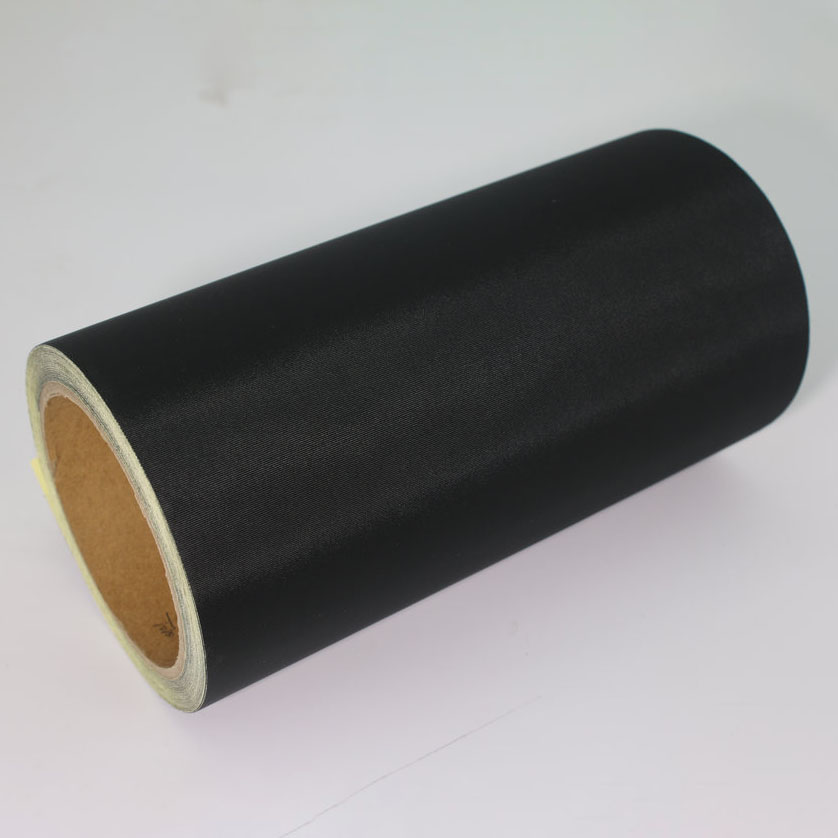

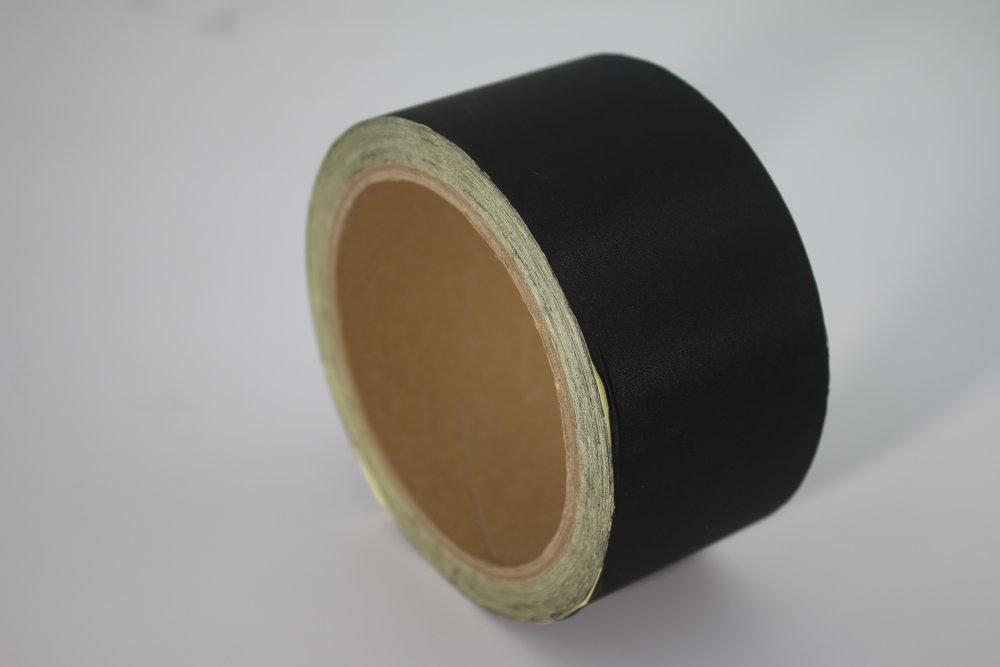

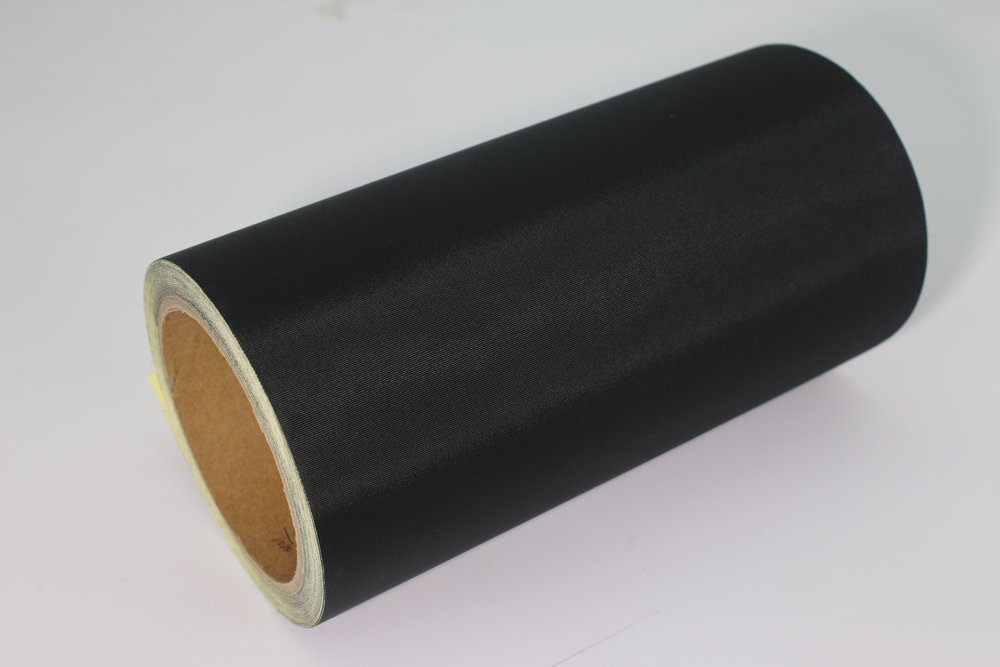

Automotive wire harness tape is a specialized adhesive tape designed to wrap, bundle, and protect electrical wires in vehicles. It helps ensure that wiring systems remain organized, insulated, and vibration-resistant throughout the car’s lifetime.

Unlike regular tapes, these are engineered to withstand:

-

High temperatures (under the hood or near the engine)

-

Chemical exposure (oil, grease, fuel)

-

Vibration and abrasion (constant vehicle movement)

-

Noise reduction (by dampening rattles or friction)

In short, it’s not just tape — it’s the first line of defense for your vehicle’s electrical system.

2. The Hidden Complexity Behind Simple Tape

It might sound simple — just wrap the wires, right? But automotive engineers know it’s much more than that.

Wire harness tape can be made from different base materials:

-

Cloth (PET or non-woven) for flexibility and low noise

-

PVC for insulation and easy wrapping

-

Fleece-backed for anti-squeak applications

-

Acetate cloth for lightweight yet durable protection

Each type is chosen based on location and function. For example, PVC tape may be used in door wiring, while non-woven fabric tape might be better for instrument panels where noise control matters most.

By the way, this connects closely to our Acetate Cloth Tape Series, which shares similar temperature resistance and flexibility properties — perfect for intricate wiring work.

3. How It Connects with Other Tape Technologies

If you’ve been following our previous blogs, you’ll notice a pattern: every tape series from Anhui Yijiayi Technology Co., Ltd. contributes to system-level performance.

-

Conductive Fabric Tape ensures EMI shielding inside electronic control units (ECUs).

-

Light-Blocking Tape prevents glare on dashboard displays.

-

Printable Tape helps label wires clearly during assembly.

-

Automotive Wire Harness Tape ties them all together, literally!

Together, they form a complete solution for automotive manufacturers seeking efficiency, safety, and aesthetics in modern vehicle design.

So yeah, it’s kinda amazing how something as “ordinary” as tape can make your car safer, quieter, and more reliable.

4. Practical Benefits That Go Beyond Protection

Automotive Wire Harness Tape isn’t just about holding wires — it adds real value to every vehicle it’s used in:

✅ Improved Safety: Keeps wires from short-circuiting or touching hot components.

✅ Simplified Maintenance: Organized wiring means easier inspection and repair.

✅ Noise & Vibration Damping: Reduces annoying rattles from wire movement.

✅ Aesthetic Cleanliness: Provides a neat, professional finish to harness assemblies.

✅ Longevity: Resists aging, moisture, and temperature fluctuations.

These advantages make it essential in EVs, hybrid cars, trucks, and even aerospace wiring systems.

And because our Yijiayi tapes are made from eco-friendly and halogen-free materials, they align perfectly with the automotive industry’s push toward sustainability.

5. Why Choose Yijiayi Automotive Wire Harness Tape

At Anhui Yijiayi Technology Co., Ltd., we don’t just sell tape — we build solutions.

Our Automotive Wire Harness Tape Series is developed using advanced coating and adhesive technology. From raw textile weaving to vacuum coating and precision die-cutting, every step is done in-house to ensure total control over quality.

We offer:

-

Customized width and length

-

Heat-resistant and flame-retardant options

-

Noise-reduction fleece tape

-

Pre-slit rolls for assembly line efficiency

-

Custom colors or printing for identification

Need something special? No problem — we can even combine conductive and insulating properties for hybrid cable assemblies.

Our goal? To make wiring management smarter, cleaner, and more durable for every vehicle type.

6. The Future: EVs and Smart Cars Need Smarter Tapes

As electric vehicles (EVs) and smart cars become the norm, wire harness systems are getting more complex and space-limited. Traditional tapes may not hold up under these conditions.

Yijiayi is already developing lightweight, high-temperature, low-VOC harness tapes to meet the demands of future mobility.

And because we manage every process — from textile production to adhesive formulation — we can guarantee performance consistency across all our products.

In essence, our automotive tape lineup doesn’t just support vehicle design; it enables it.

From electronic shielding to display optimization, and now automotive wiring protection, Yijiayi’s full range of industrial tapes work together to enhance safety, performance, and reliability.

Every piece of tape we produce is part of a bigger story — one of precision, protection, and innovation.

5 Ways Nylon Cloth Tape Solves Everyday Industrial and Consumer Challenges

5 Ways Nylon Cloth Tape Solves Everyday Industrial and Consumer Challenges

How Printable Tape Improves Labeling Efficiency Across Industries?

How Printable Tape Improves Labeling Efficiency Across Industries?

How Light-Blocking Tape Enhances Product Performance in Modern Devices?

How Light-Blocking Tape Enhances Product Performance in Modern Devices?

Why Light-Blocking Tape Matters More Than You Think in Modern Electronics

Why Light-Blocking Tape Matters More Than You Think in Modern Electronics

Why Nylon Cloth Tape Is the Most Underrated Tool in Every Industry

Why Nylon Cloth Tape Is the Most Underrated Tool in Every Industry

How Automotive Wire Harness Tape Protects and Organizes Your Vehicle Wiring System

How Automotive Wire Harness Tape Protects and Organizes Your Vehicle Wiring System

Light-Blocking Tape: Why It Matters in Modern Display and Lighting Design

Light-Blocking Tape: Why It Matters in Modern Display and Lighting Design

Printable Tape: How It Enhances Design and Functionality

Printable Tape: How It Enhances Design and Functionality

Why Is Conductive Cloth Tape So Important in Modern Electronics?

Why Is Conductive Cloth Tape So Important in Modern Electronics?

How Conductive Cloth Tape Improves Electronic Shielding and EMI Protection

How Conductive Cloth Tape Improves Electronic Shielding and EMI Protection