Why is Automotive Wire Harness Tape Essential for Vehicle Safety and Performance?

When we think of car safety, most people imagine airbags, seat belts, or brake systems. But here’s the catch — one of the most overlooked yet vital components in any vehicle is the automotive wire harness tape. Without proper insulation and bundling of wires, a car’s electrical system can face serious problems, from short circuits to fire hazards. So, why exactly is this type of tape so important? Let’s dive in.

What is Automotive Wire Harness Tape?

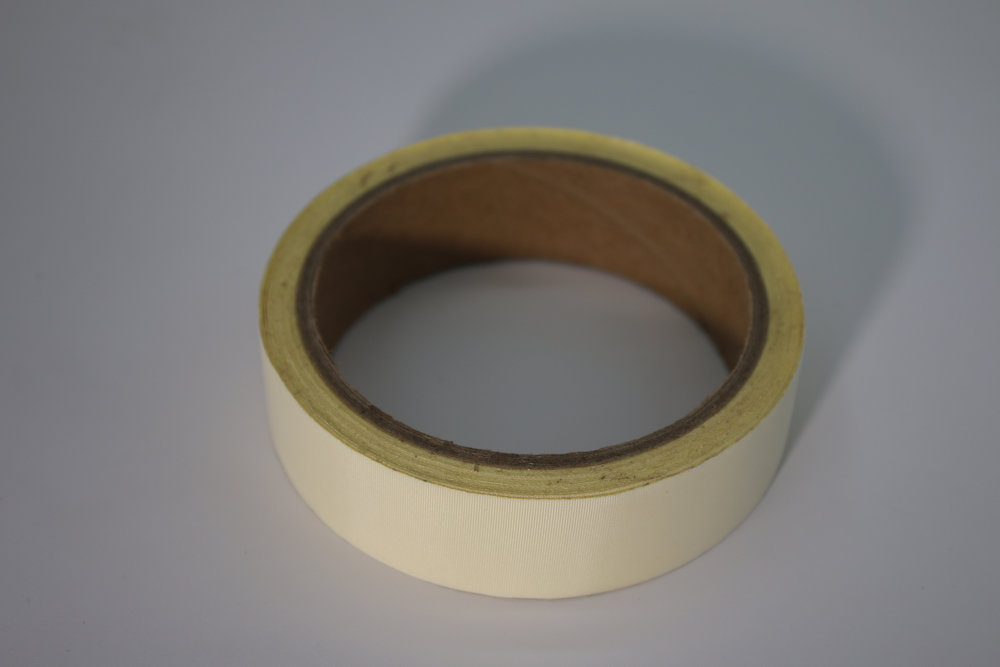

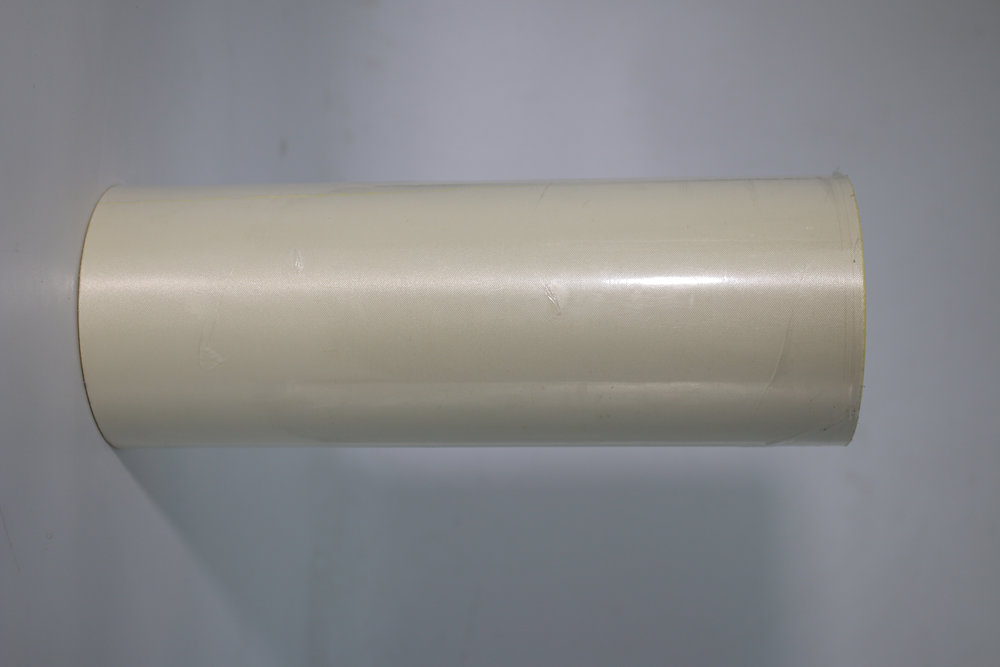

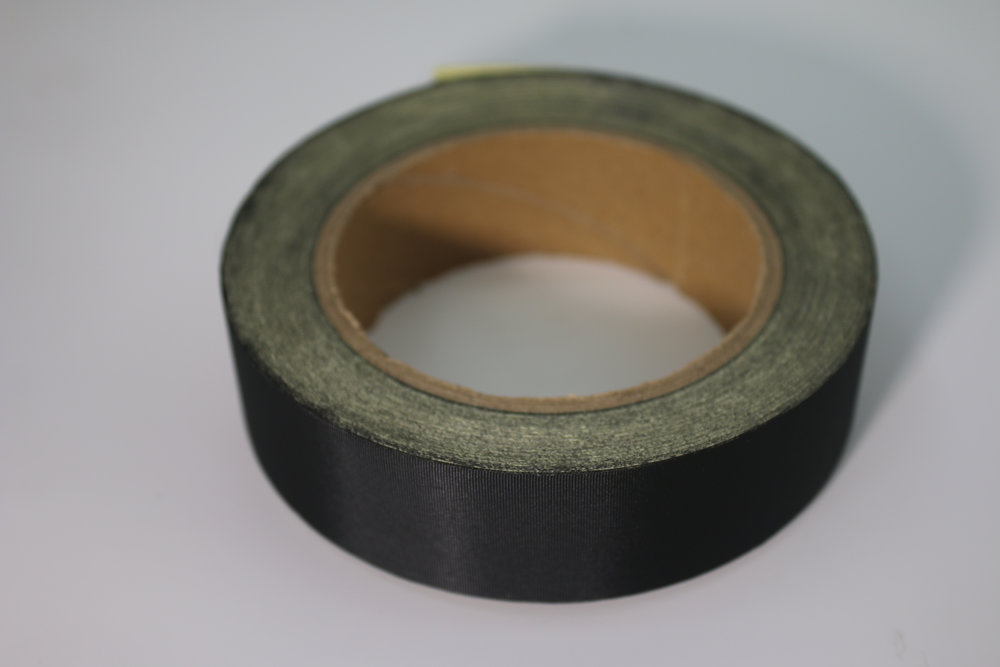

Automotive wire harness tape is a specialized adhesive tape designed to bundle, insulate, and protect electrical wires inside vehicles. Unlike standard tapes, it must withstand extreme heat, vibration, abrasion, and exposure to oil or moisture.

At Anhui Yijiayi Technology Co., Ltd., we produce a wide range of wire harness tapes — including cloth tapes, PET tapes, and fleece tapes — tailored to the needs of the automotive industry. As a China-based manufacturer and supplier, we work with OEMs and aftermarket companies worldwide.

Key Functions of Wire Harness Tape

So, why not just use regular tape? Well, automotive environments are tough. Here are the major functions:

-

Bundling and Organization – Keeps hundreds of wires neatly grouped, making assembly and maintenance easier.

-

Abrasion Resistance – Prevents wires from rubbing against metal or sharp edges.

-

Heat Resistance – Survives engine bay temperatures without losing adhesive strength.

-

Noise Reduction – Fleece and fabric tapes reduce rattling sounds inside the cabin.

-

Moisture and Oil Protection – Prevents corrosion and short circuits in damp conditions.

Different Types of Automotive Wire Harness Tapes

Not all tapes are created equal. Choosing the right one depends on where in the vehicle it will be used:

-

Cloth/Fleece Tape – Ideal for interior use, offering noise reduction.

-

PET Tape – Thin and durable, perfect for high-temperature areas.

-

PVC Tape – Commonly used for basic bundling and insulation.

-

Acrylic or Rubber Adhesive Tapes – For strong, lasting adhesion.

-

Heat-Resistant Tapes – For engine compartments and exhaust areas.

(And yep, using the wrong tape here can cause real trouble later — don’t cut corners.)

Why OEMs and Suppliers Prefer Custom Solutions

Automotive manufacturers rarely rely on off-the-shelf tapes. Instead, they need customized sizes, colors, and adhesive strengths to meet strict industry standards. That’s why we provide:

-

Custom widths and roll lengths

-

Flame-retardant and ROHS-compliant options

-

OEM logo printing

-

Easy-tear or smooth-finish options

-

Bulk and wholesale supply for production lines

This flexibility makes us a reliable Chinese automotive tape supplier for global clients.

Real-World Impact: Safety and Performance

Think about it — modern cars have over 1,000 meters of wiring. Without proper harnessing, wires can loosen, rub against parts, and even spark fires. Automotive wire harness tape plays a hidden but critical role in preventing these risks.

For example:

-

In electric vehicles, tapes must also handle high-voltage insulation.

-

In luxury cars, noise-reducing fleece tape enhances cabin comfort.

-

In trucks or construction vehicles, tapes must resist oil, mud, and vibration daily.

Should You Source From a China Manufacturer?

Many B2B buyers ask this. And honestly, the answer is yes, if you choose the right partner. Working with a China-based supplier like Anhui Yijiayi Technology Co., Ltd. gives you:

-

Competitive factory pricing

-

Stable production capacity for OEM orders

-

Customized solutions with fast turnaround

-

Global shipping and after-sales support

And let’s be real — sourcing directly saves you both money and time.

Automotive wire harness tape may not get the spotlight like flashy car parts, but it’s absolutely essential for safety, performance, and comfort. By choosing the right tape and supplier, manufacturers can avoid costly failures and ensure long-lasting reliability.

At Anhui Yijiayi Technology Co., Ltd., we provide not just products but partnerships, offering direct factory supply, OEM customization, and wholesale distribution worldwide.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures